When I first started learning about logistics, I kept running into the term container drayage.

At first, it sounded complicated, but I quickly realized it’s just a simple part of moving containers from ports to the next stop in the supply chain. You see it in action every day if you’re around ports or rail yards, but most people don’t even notice it happening.

Understanding drayage will make the whole shipping process a lot clearer for you. It’s the piece that connects global shipping to local delivery, and I’m here to give you that piece.

Let’s start with the basics so you can see exactly what it means and why it matters.

What is Container Drayage?

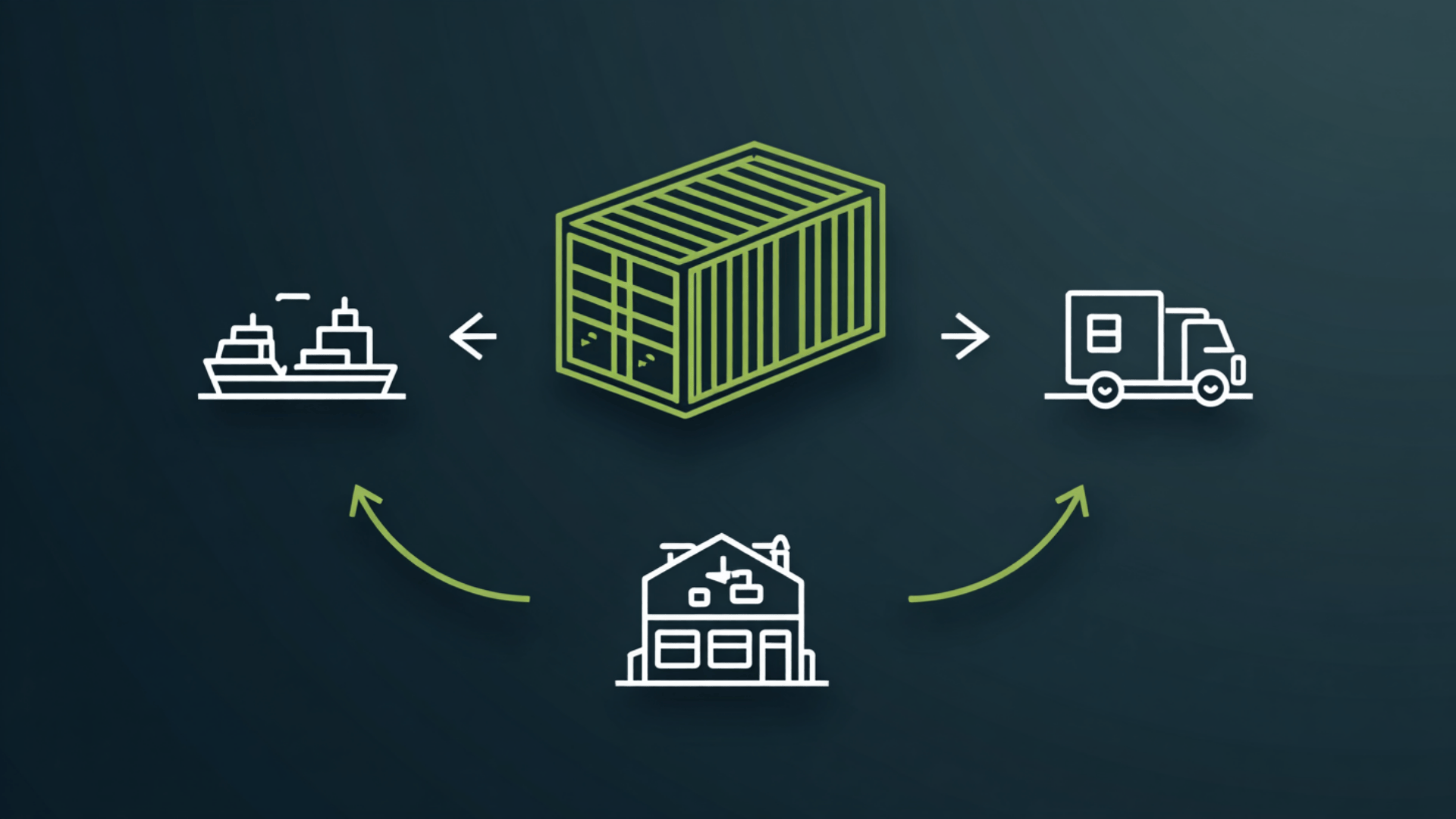

Container drayage is simply the short trip a shipping container takes after it arrives at a port or rail yard. It usually involves a truck moving the container to a warehouse, distribution center, or another local facility.

It matters because without this step, goods would never leave the port. Drayage keeps the supply chain moving, avoids storage fees, and makes sure products get to where they need to be on time.

How Container Drayage Works

Let me walk you through how it works. Drayage is one of those behind-the-scenes steps that happens every day but often goes unnoticed.

- Step 1: Ship Arrival. A container comes into a port by ocean vessel.

- Step 2: Container Pickup. A drayage truck driver collects it from the port or rail yard.

- Step 3: Short-Haul Move. The container is hauled a short distance, usually within the same city or region.

- Step 4: Delivery Point. It’s dropped at a warehouse, distribution center, or rail terminal for the next leg.

- Step 5: Final Transition. From there, the goods continue on their journey until they reach stores, businesses, or homes.

This short trip is also what connects different types of transport, like ships, trucks, and trains. Without drayage, intermodal shipping would break down because the container wouldn’t move smoothly from one mode of transport to the next.

Types of Container Drayage

Not all drayage moves are the same. The type depends on where the container is going and how it’s handled along the way.

1. Pier Drayage

This is the most common type. A truck picks up or delivers containers directly at the seaport. It’s often the first move after a ship arrives.

2. Intra-Carrier vs. Inter-Carrier

- Intra-Carrier Drayage: The same carrier moves the container within its own network, like from a rail terminal to a nearby warehouse.

- Inter-Carrier Drayage: One carrier hands the container off to another, usually between different terminals or service providers.

3. Drop & Hook vs. Live Load/Unload

- Drop & Hook: The driver drops off an empty container and hooks up to a loaded one. This saves time because there’s no waiting.

- Live Load/Unload: The driver waits while the container is loaded or unloaded at the facility. It takes longer, but it works for businesses that don’t have extra space for containers.

4. Expedited Services

This is for shipments that can’t wait. Expedited drayage moves containers as quickly as possible, often for time-sensitive goods like fresh food or urgent retail orders.

Each type serves a different purpose, and knowing the options helps you choose the best fit for your shipping needs.

Container Drayage Costs and Fees

When you move containers, the costs can add up quickly. Drayage fees are one of the most common charges, and understanding them helps you stay in control of your shipping budget.

What is a Drayage Fee?

A drayage fee is the charge for hauling a container a short distance, usually from a port or rail yard to a warehouse, distribution center, or another facility.

It covers the driver, truck, fuel, and use of chassis equipment. Think of it as the “first or last mile” cost that makes the rest of the supply chain possible.

Factors Influencing Costs

Several details affect how much you’ll pay for drayage:

- Distance: The farther the move, the higher the cost. Even though drayage is short-haul, miles add up fast.

- Port Congestion: Busy ports often lead to delays. Drivers spend more time waiting, which raises rates.

- Wait Time: If a driver has to wait for the container to be loaded or unloaded, hourly fees are added.

- Chassis Use: Not every container comes with a chassis. If one has to be rented, there’s an extra charge.

- Fuel Prices: Rising fuel costs can push drayage fees higher without notice.

The bottom line: time and equipment are the biggest cost drivers. The longer a container sits, the more you’ll pay.

Demurrage vs. Detention

These two charges sound similar, but they mean different things:

- Demurrage: A storage fee charged by the port or terminal when your container stays there too long.

- Detention: A fee charged when you hold on to the container or chassis past the free time allowed.

Both are avoidable if drayage is scheduled right away and handled smoothly. Quick planning often saves hundreds of dollars.

Real-World Cost Examples

Rates vary by port and region, but here are some common scenarios:

- Local drayage within a metro area: $100–$250 per container

- Port to nearby warehouse (20–50 miles): $250–$400

- Congested port with long wait times: $500 or more

I know from experience that businesses that line up drayage before a vessel even arrives save the most. When you’re ready ahead of time, you avoid the “extra day” fees that eat into your profit.

Why Drayage Matters in the Supply Chain

Drayage may look like a small step, but it has a big impact on the entire supply chain. When containers don’t move on time, everything else slows down, and costs can rise quickly.

One of the biggest reasons drayage matters is its role in avoiding costly delays. Ports and rail yards charge extra if containers sit too long, and those fees add up fast.

Having drayage in place keeps containers moving, reduces storage time, and prevents surprise charges like demurrage and detention.

Drayage also supports both imports and exports. Every international shipment depends on it at some point, whether it’s bringing containers out of the port after arrival or moving export goods back in.

Without drayage, global trade would stall because goods would never leave the entry or exit point.

There’s also a direct link between good drayage and customer satisfaction. When containers move quickly from the port to a warehouse and then to stores, deliveries stay on schedule.

I’ve noticed how much smoother operations run when drayage is planned in advance; it helps keep promises to customers and builds long-term trust.

Container Drayage Services & Solutions

Drayage providers often go beyond simple container moves. They offer added services that make shipping easier and help avoid delays. Here are some of the most common options:

| Service | What It Means |

|---|---|

| Transloading | Goods are moved from a container into another truck or trailer for final delivery. |

| Warehousing | Containers are taken to a nearby warehouse where goods are stored until needed. |

| Bonded Drayage | Containers move under customs bond without duties cleared right away. |

| Technology & Tracking | Real-time tracking and digital scheduling provide better visibility and fewer delays. |

These extra services give you more flexibility and control. By choosing the right mix, you can keep your supply chain running smoothly and reduce the risk of unexpected costs.

Common Challenges in Container Drayage

Drayage can run into problems that slow down shipments and add extra costs. Knowing these challenges ahead of time makes it easier to plan around them.

- Port congestion: Busy ports often create long delays, making it harder to move containers on schedule.

- Chassis shortages: Without enough chassis, containers can’t leave the terminal, which causes expensive backups.

- Driver shortages & wait times: A limited driver pool and long on-site waits can raise rates and cut into capacity.

- Regulatory compliance: Rules around customs, safety, and environmental standards can slow down operations.

These challenges are part of the reality of container drayage, but the good news is they can be managed with smart planning and dependable partners.

Choosing the Right Drayage Provider

The provider you choose plays a big role in keeping your containers moving on time. A strong partner can cut delays and costs, while the wrong one may create constant headaches.

Here’s a checklist you can use when deciding:

Key Questions to Ask

- How do you handle port congestion and unexpected delays?

- What technology do you use for scheduling and tracking containers?

- Do you offer services like transloading, warehousing, or bonded drayage?

- Can you provide clear, upfront pricing without hidden fees?

Signs of a Reliable Provider

- Strong record of on-time performance

- Open communication and quick updates

- Flexible service options that fit your needs

- Experience with your type of cargo and industry

Regional Expertise to Consider

- Knowledge of specific port or rail yard rules

- Familiarity with local traffic patterns and access points

- Connections with terminals and carriers in the region

Using this checklist helps you spot the providers who can truly support your business.

The right partner keeps your containers moving and gives you confidence that your supply chain won’t break down at the first sign of trouble.

Future of Container Drayage

Drayage is changing as the industry looks for ways to be more efficient and sustainable. What used to be a straightforward trucking job is now supported by new tools, cleaner equipment, and smarter planning.

Sustainability is at the top of the list. Ports and carriers are testing electric trucks and alternative fuels to cut emissions in busy port cities. These efforts not only help the environment but also prepare businesses for stricter regulations that are already starting to roll out.

Technology is another key driver. Real-time tracking and digital scheduling give better visibility into container moves and help avoid costly surprises. I’ve seen how much easier it is for companies using these tools; they can plan ahead and respond faster when delays happen.

Automation is slowly taking hold as well. Smarter gate systems, digital paperwork, and streamlined scheduling reduce wait times and keep containers moving. It won’t replace drivers, but it does make day-to-day operations smoother.

The future of drayage is all about being faster, cleaner, and more reliable. Companies that adopt these changes early will cut costs, reduce risks, and build stronger supply chains.

Wrapping Up

Container drayage may seem like a small piece of the shipping process, but it plays a huge role in keeping goods moving on time.

From avoiding costly delays to supporting imports and exports, drayage is the step that connects ports, warehouses, and customers. With new technology, greener equipment, and smarter planning, the future of drayage looks even more efficient and reliable.

If you understand how drayage works and what to look for in a provider, you’ll be better prepared to keep your supply chain running smoothly.

Want to learn more about logistics and related topics? Check out my other blogs where I break down shipping, transport, and supply chain basics for you.