Shipping can feel tricky, and the choices you make often decide whether things run smoothly or not. I’ve seen how the wrong option can lead to delays, surprise costs, or even damaged freight.

That’s where full truckload shipping comes in. It isn’t only about filling a trailer, it’s about gaining more control, keeping timelines steady, and cutting out avoidable risks.

The real advantage isn’t just speed, it’s how FTL reduces weak points in your supply chain.

If you’ve ever wondered when a dedicated truck makes more sense than shared space, I will give you clear answers. Let’s kick things off by breaking down exactly what full truckload shipping is and why it matters.

What is Full Truckload (FTL) Shipping?

Full truckload shipping, or FTL, is when one shipment fills the entire truck. Nothing gets shared with other freight; it’s all for your goods.

I’ve seen how this makes shipping smoother. The truck goes straight from pickup to delivery, with fewer stops along the way. That usually means faster transit and less chance of damage.

Key points to know:

- Dedicated truck: the trailer is only for your shipment.

- Direct routing: the load moves from start to finish without extra stops.

- Fewer transfers: less handling keeps your freight safer.

If you’ve got a big load or need something delivered quickly, FTL often makes the most sense.

Full Truckload vs. Other Shipping Modes

Full truckload (FTL) isn’t always the cheapest, but it’s often the most reliable when speed and safety matter. Even full container load (FCL) in ocean freight has a similar idea.

Other options like less-than-truckload (LTL) or partial truckload (PTL) work better for smaller shipments.

| Mode | How It Works | Best For | Key Trade-Offs |

|---|---|---|---|

| FTL (Full Truckload) | One shipment fills the entire truck | Large, fragile, or time-sensitive freight | Higher cost but faster and safer |

| LTL (Less-Than-Truckload) | Multiple shipments share space in one truck | Small to medium loads | Cheaper but slower, more handling |

| PTL (Partial Truckload) | Shares space but fewer shippers than LTL | Medium loads, not quite full | Flexible pricing, moderate speed |

| FCL (Full Container Load) | One shipment fills an entire ocean container | International freight | Similar to FTL but for ocean shipping |

If you know how each mode works, it’s easier to match your freight with the option that saves you the most time and money.

When Should You Choose FTL?

Think of FTL as the right fit when your shipment checks certain boxes. Here’s a quick way to know if it’s the right choice:

- Big load: Your freight takes up most or all of a trailer.

- Fragile or high-value: You want less handling to keep it safe.

- Time-sensitive: You need faster delivery with no extra stops.

- Special needs: Your shipment requires reefer, flatbed, or other specialized trailers.

If two or more of these apply, full truckload is usually the best option.

How Full Truckload Shipping Works (Step-by-Step)

Full truckload shipping follows a straightforward process. I like to think of it as a simple journey from start to finish, with only a few key steps in between.

When you know what happens at each stage, it’s easier to plan and avoid surprises.

1. Booking the Truck

You or your broker lines up a carrier. At this stage, you’ll need to share details like shipment size, weight, pickup and delivery locations, and if any special equipment is required.

Being clear up front helps carriers give accurate rates and keeps surprises out of the picture.

2. Loading at Pickup

The driver arrives at your dock or warehouse. Your team is responsible for loading the freight safely and securing it in the trailer.

Once the load is in, the driver seals the trailer. This seal is very important. It shows the shipment hasn’t been touched until it reaches the destination.

3. Direct Transit

The truck goes straight to the delivery point without stopping to add or remove other freight. This is one of the biggest advantages of FTL: fewer stops, less handling, and a quicker trip.

Depending on distance, transit can take a day or several, but it’s generally faster than shared loads.

4. Unloading at Delivery

At the final location, the trailer is unsealed and the freight is unloaded. Someone signs off to confirm the goods arrived in good condition. This paperwork matters if there are ever claims or disputes later on.

Each step is built to save time and reduce risks. The fewer hands involved, the better your chances of a smooth delivery.

Factors Affecting Costs and Pricing

Figuring out FTL pricing can feel confusing at first, but it really comes down to a few key factors. Once you understand how rates are set, it’s easier to budget and avoid surprises.

How rates are structured:

Most carriers charge by the mile, usually between $2.50 and $3.50 per mile for a standard dry van. Some lanes run on a flat rate, especially for repeat routes.

In certain cases, carriers may even charge by the hour, often on short or regional hauls.

What affects the cost:

- Fuel: Diesel prices change often, and surcharges are common.

- Demand and seasonality: Busy lanes or peak seasons, like holidays or harvest time, usually push rates higher.

- Equipment: Reefers, flatbeds, or other specialty trailers come at a premium.

- Extra fees: Things like detention for long loading times or liftgate service can raise the final bill.

Real-world cost ranges:

- Short hauls (under 500 miles): around $1,000–$3,000.

- Medium hauls (500–1,500 miles): about $2,000–$5,000.

- Long hauls (1,500+ miles): anywhere from $4,000–$10,000+.

Knowing these numbers gives you a clearer picture of what to expect. If you keep an eye on fuel prices and plan around peak seasons, you can often manage your costs more effectively.

Common Problems in FTL Shipping (and Solutions)

Even with all the benefits of FTL, a few issues can come up along the way. The key is knowing what to expect and how to handle it before it becomes a bigger problem.

- Capacity shortages: During busy seasons or in high-demand lanes, trucks may be limited. Booking early and keeping pickup times flexible helps improve your chances of finding available capacity.

- Accessorial charges: Extra fees for delays, detention, or added services can quickly increase shipping costs. Keeping freight ready on time and setting clear expectations with carriers helps reduce these charges.

- Damages and insurance: Even though FTL involves less handling, damage is still possible. Using strong packaging, loading securely, and confirming adequate insurance keeps your freight better protected.

Planning ahead for these challenges makes shipping smoother and helps you avoid costly surprises. With a few precautions, FTL can remain both reliable and efficient.

Industries That Benefit Most from FTL

Manufacturing often requires the steady movement of raw materials and large shipments of finished goods. FTL works well here because it keeps loads moving in bulk with fewer delays.

In retail and e-commerce, high volumes of products need to reach stores and fulfillment centers quickly. Dedicated trucks help avoid slowdowns and make sure shelves stay stocked and orders go out on time.

The food and beverage industry depends on refrigerated trailers for perishable freight. FTL reduces extra handling and keeps temperatures consistent, which is critical for items like meat, dairy, and frozen foods.

Automotive and machinery shipments frequently involve oversized equipment or heavy parts. These loads need both the space and the specialized equipment that a full truck provides, along with added security during transit.

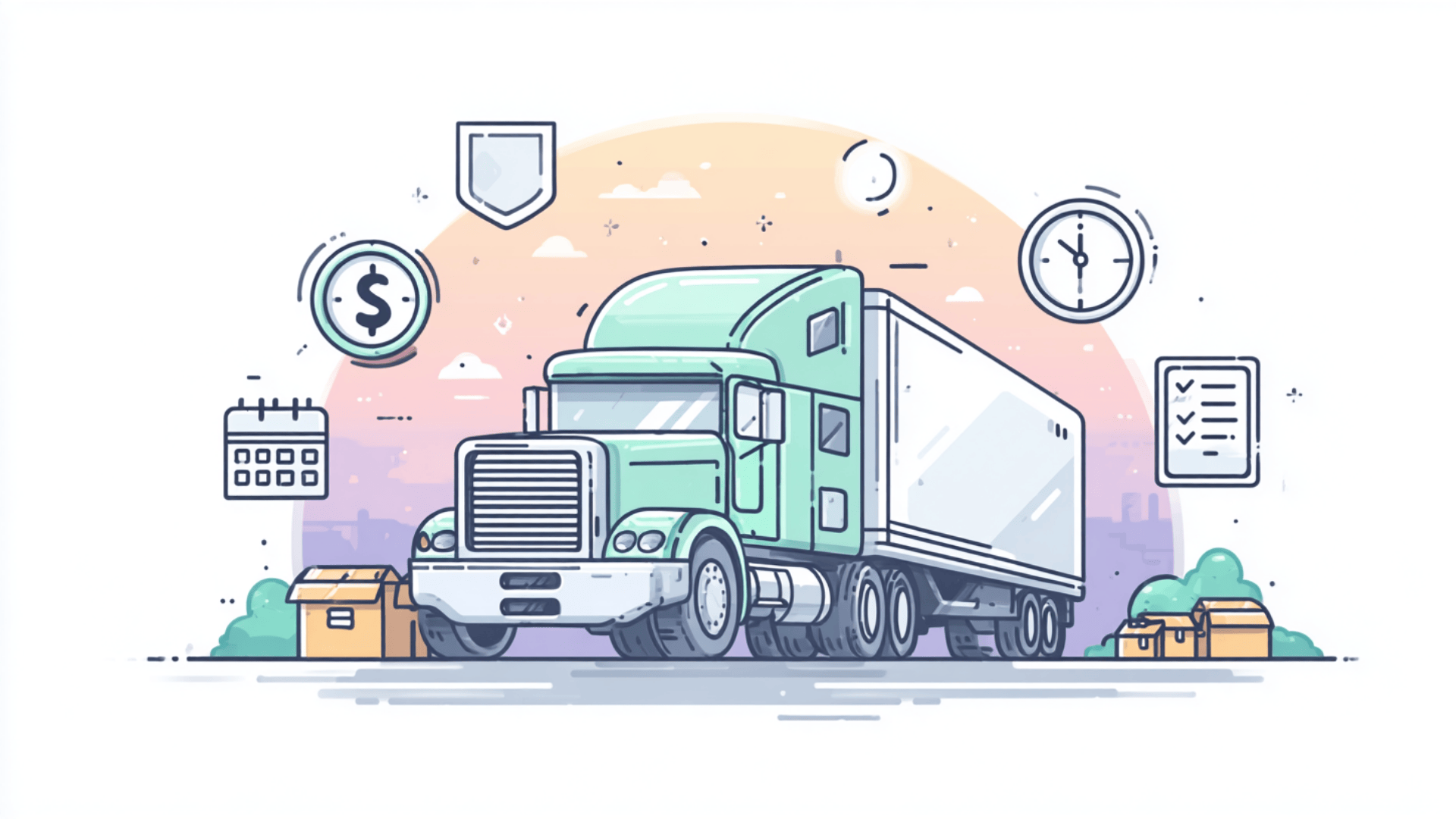

Choosing the Right FTL Provider and Helpful Tools

Finding the right FTL provider comes down to trust and fit. You’ll want a carrier that’s reliable, offers solid tracking tools, and keeps claims low.

Consistent on-time delivery, transparent pricing, and equipment suited to your freight are all signs you’re in good hands. A simple checklist like this helps:

- Reliability

- Tracking

- Claims ratio

- Support

- Transparency

To make the process easier, a few tools can help. Freight calculators give quick cost estimates so you know what to expect before booking.

A shipment preparation checklist keeps your freight ready and avoids delays or extra charges. Rate comparison charts let you see pricing differences across providers, helping you choose the most cost-effective option with confidence.

Together, clear criteria and simple tools make choosing an FTL provider less of a gamble and more of a smart, informed decision.

Wrapping Up

I like the control you get when a truck runs only your freight. What often gets overlooked is how FTL strengthens supply chains by reducing weak points like unnecessary transfers and unpredictable delays.

Choose full truckload when consistency matters more than chasing the lowest rate. I’ve found that when you cut out extra stops and handling, you also cut down on the risks that can slow you down.

Thinking beyond the basics and planning around demand cycles, equipment needs, and carrier partnerships helps you get the most from this shipping method.

If you want to keep learning simple ways to improve your shipping, take a look at my other blogs on the site for more useful tips and ideas.