When most people think about supply chains, they picture products moving forward, from factory to store to your hands. But what happens when those products need to go back?

That’s where reverse logistics comes in. I’ll show you the process businesses use to handle returns, repairs, recycling, and more. Far from being just an afterthought, it’s now a critical part of modern supply chains.

Done well, it saves money, reduces waste, and keeps customers happy. To understand why it matters, let me take you through the basics and break down exactly what reverse logistics is and how it works.

What is Reverse Logistics?

Reverse logistics is the process of moving products back from customers to the seller or manufacturer. It’s the opposite of what we usually think of in supply chains, where goods go forward from factory to store to buyer.

Think of it this way: forward logistics gets the product into your hands, while reverse logistics is what happens when the product leaves your hands and goes back. That could be for a return, a repair, or even recycling.

The 5 R’s of Reverse Logistics Explained

The “5 R’s” make it easier to understand the core activities that drive reverse logistics. Each one plays a role in reducing waste and creating value.

- Returns: Products sent back by customers for refunds, exchanges, or store credit. A smooth returns process keeps customers happy and builds trust.

- Reselling: Returned items that are still in good condition can be sold again, either at full price or through clearance and outlet channels.

- Repairs: Damaged or defective items can often be fixed and made functional again, extending their life and reducing the need for replacements.

- Recycling: Products that can’t be reused or repaired may still contain valuable materials, like plastics, metals, or glass, that can be recycled.

- Recovery: Businesses can recover value by reclaiming usable parts, packaging, or materials, such as refillable bottles or pallets.

Together, the 5 R’s highlight how reverse logistics isn’t just about handling returns; it’s about finding ways to get value back at every step.

Types of Reverse Logistics

Reverse logistics takes different forms depending on the reason a product moves backward through the supply chain. Each type has its own role in helping businesses.

1. Consumer Returns

This is the most common form of reverse logistics. It happens when you buy something and decide to send it back. Maybe the size was wrong, or the item just wasn’t what you expected.

Businesses need clear systems to receive, inspect, and process these returns quickly, so you don’t feel stuck waiting.

2. Warranty and Repair

Sometimes products break down or stop working during the warranty period. Instead of throwing them away, companies collect and repair them. Once fixed, they can be sent back to you or resold.

I’ve found this process not only saves money but also builds trust because you know the brand will stand behind its product.

3. End-of-Life Recycling

When products reach the point where they can’t be used again, they still may have value in their parts or materials.

Electronics, for example, often get broken down for metals or plastics that can be reused. This type of reverse logistics keeps waste out of landfills and helps the environment.

4. Reuse of Packaging and Containers

Many companies now collect packaging so it doesn’t go to waste. Think about refillable milk bottles, reusable shipping boxes, or even pallets. By reusing containers, businesses cut costs and reduce trash, while you get a more eco-friendly shopping experience.

5. Failed Deliveries

Not every package makes it to your doorstep. Sometimes addresses are wrong, or no one is available to receive the order. In those cases, the item is returned to the warehouse or seller.

A strong reverse logistics process makes sure these products don’t just sit idle but get resold or reused.

Benefits and Challenges of Reverse Logistics

Reverse logistics can create real value for businesses, but it also comes with hurdles that need careful planning. Understanding both sides gives a clearer view of how it works in practice.

- Cost Reduction: Reverse logistics helps cut costs by recovering materials and reselling refurbished items. However, setting up the system can be costly and resource-intensive.

- Improved Customer Satisfaction & Loyalty: A smooth return process increases customer satisfaction and loyalty. But poor returns management can lead to frustration and damage customer relationships.

- Sustainability & Environmental Impact: Reverse logistics reduces waste by recycling and reusing products, supporting sustainability. But adopting eco-friendly practices can require significant investment and effort.

- Data Insights for Product Improvement: Analyzing returns provides valuable data to improve products and customer satisfaction. However, managing and acting on this data can be complex and require advanced systems.

- Revenue from Resale/Refurbished Items: Refurbishing and reselling returned items generates additional revenue. However, the process can be expensive and may not always yield a profit if not managed well.

- Asset Recovery: Reverse logistics recovers valuable assets, like electronics or packaging, to reduce waste. However, efficient tracking and logistics infrastructure are required to manage this properly.

- Fraud and Abuse: Fraudulent returns, like using products and then returning them, can increase costs and complexity. Without the right systems, businesses may struggle to detect and manage abuse

In short, reverse logistics offers clear financial, customer, and environmental benefits, but businesses need the right systems in place to overcome the challenges that come with it.

Reverse Logistics Process Step-by-Step

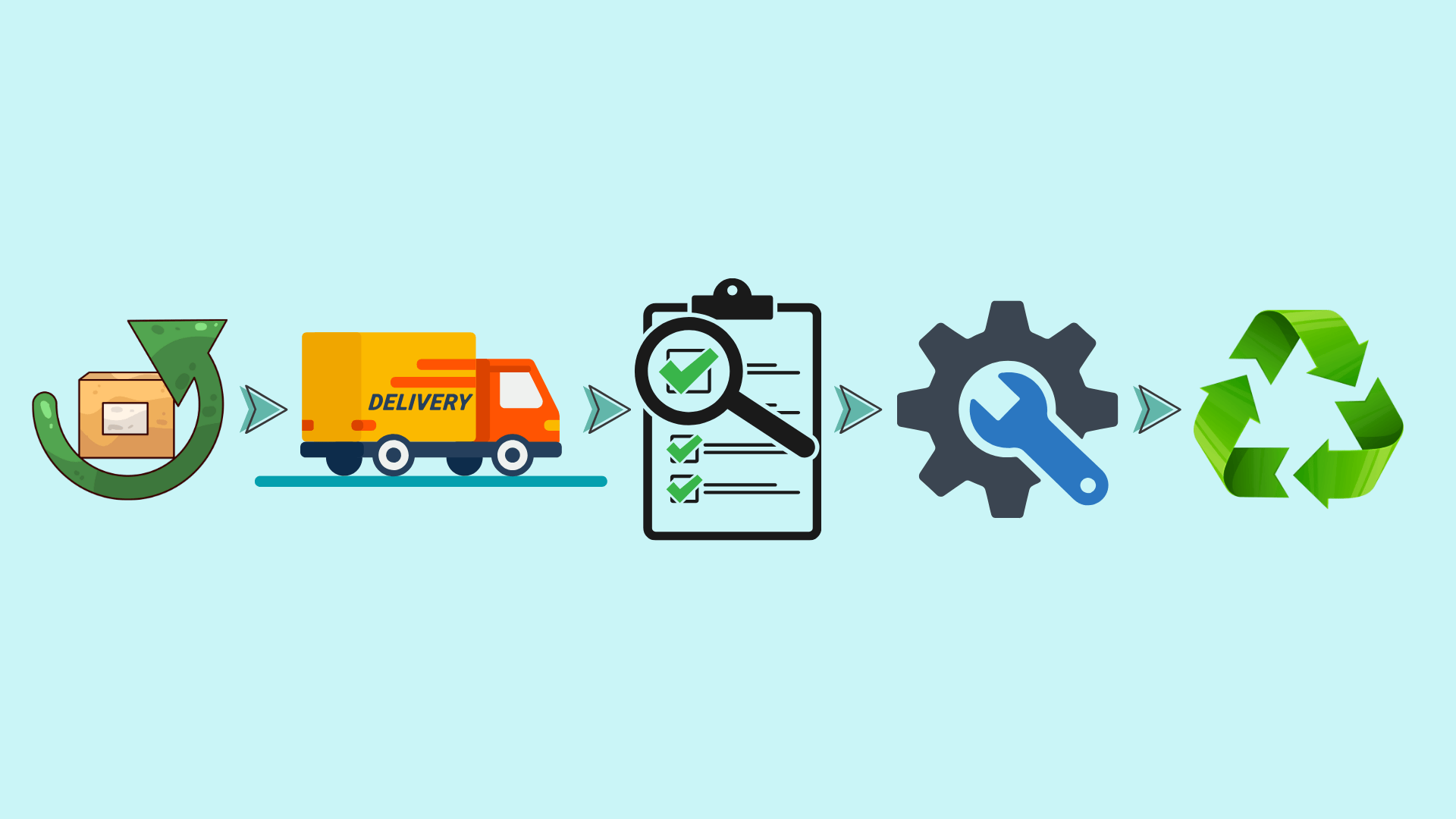

The reverse logistics process may look different depending on the business, but most follow the same core steps. Here’s a simple breakdown of how it usually works:

Step 1: Return Initiation

The process starts when a customer decides to return or send back an item, often through an online request, a store visit, or a delivery pick-up.

Step 2: Transportation and Collection

The product is collected and sent to a warehouse, return center, or repair facility. Smooth transportation is key to keeping costs low and turnaround times short.

Step 3: Inspection and Sorting

Once the item arrives, it’s inspected to decide what happens next: resell, repair, recycle, or dispose. Sorting correctly at this stage prevents wasted effort.

Step 4: Processing and Action

Products that can be resold are restocked, items needing repair are fixed, and materials suitable for recycling are sent for processing.

Step 5: Disposal or Recovery

If the item has no resale or reuse value, it’s disposed of responsibly. In some cases, usable parts or packaging are recovered to reduce waste.

By following these steps, businesses can handle returns efficiently, save resources, and make the most out of products that come back through the supply chain.

Reverse Logistics by Industry

Reverse logistics varies by industry, with each facing different challenges and opportunities.

In e-commerce, returns are common, especially for clothing and electronics. Efficient systems are needed to process returns quickly, restock items, and issue refunds to maintain customer trust.

In retail, both online and in-store returns are managed. Many retailers allow customers to return online purchases in-store, making the process more convenient and reducing wasted inventory.

In manufacturing, reverse logistics is used for defective parts, repairs, and managing outdated inventory. This helps cut storage costs and reduce waste.

In healthcare and pharma, reverse logistics handles expired drugs, reusable devices, and clinical trial kits. Compliance is key, ensuring items are properly disposed of or recycled.

In the food and beverage industry, reverse logistics deals with reusable packaging and expired products. It ensures containers are cleaned and reused, while unsellable items are disposed of properly.

Across all industries, reverse logistics helps recover value, improve efficiency, and reduce waste.

Real-World Examples of Reverse Logistics

Reverse logistics isn’t just theory. Many companies use it every day to cut costs, reduce waste, and keep customers happy. Here are a few examples you might recognize:

1. Amazon Return Process

2. Oberweis Milk Bottles

Oberweis Dairy uses refillable glass bottles for milk. Customers return the empties, which are cleaned, sanitized, and refilled. This simple process saves money, reduces packaging waste, and builds loyalty through convenience.

3. Coffee Pod Recycling Programs

Some coffee brands run mail-back or drop-off programs for used pods. Instead of sending pods to landfills, the aluminum, plastic, and leftover grounds are separated and reused. It’s a way to handle waste from single-use products responsibly.

4. Pharma and Clinical Trial Kit Reuse

In the pharmaceutical industry, clinical trial kits are often collected, sanitized, and reused when possible. Packaging and components that meet safety standards are repurposed, which saves money and reduces environmental impact without risking compliance.

These examples show how reverse logistics adapts to different industries. Whether it’s retail, food, or healthcare, the goal stays the same: recover value while keeping customers satisfied.

Innovations in Reverse Logistics

The field of reverse logistics is constantly evolving with new technologies that help businesses improve efficiency and reduce costs. Here are some key innovations making a big impact.

AI fraud detection is becoming a game-changer in reverse logistics. It helps companies spot patterns of fraudulent returns, preventing misuse of return policies. By analyzing return data, AI can flag suspicious activities, saving businesses from unnecessary losses.

Blockchain for traceability is another innovation helping businesses track products throughout the reverse logistics process. With blockchain, every return or item can be traced, ensuring transparency, reducing errors, and improving accountability.

IoT tracking in asset recovery allows companies to track valuable items, such as electronics or packaging, in real-time. This improves recovery rates and ensures that assets are returned or reused quickly and efficiently.

Sustainable packaging is helping reduce waste in the reverse logistics process. Companies are turning to recyclable and reusable packaging materials, which cuts down on the environmental impact of shipping and returns.

These innovations are helping businesses make reverse logistics more efficient, secure, and eco-friendly.

How to Build an Effective Reverse Logistics Strategy

Building an effective reverse logistics strategy requires careful planning and execution. Here’s a simple step-by-step framework to guide businesses through the process:

Start by mapping your return process. Understand how products flow from customers back to your warehouse, and identify key points where improvements can be made, such as streamlining returns, sorting, and repairs.

Next, implement technology. Use tracking software, AI, and automated systems to manage returns more efficiently and reduce errors. Investing in the right tools helps speed up the process and ensures accuracy.

Optimize your return policies. Make returns easy for customers while protecting your business. Clear guidelines on what can be returned and under what conditions will help reduce unnecessary returns.

To reduce costs and waste, focus on refurbishing or reselling returned items when possible. Also, streamline packaging to reuse materials and reduce shipping waste.

Finally, set key performance indicators (KPIs) to measure success. Track metrics like return rate, processing time, recovery rates, and customer satisfaction to assess the effectiveness of your strategy.

Reverse Logistics Providers and Platforms

Choosing the right reverse logistics provider is crucial to optimizing your return process. Here’s a look at some key players in the market and what they offer:

ReBound Returns

ReBound offers comprehensive software and a global network to manage returns across various industries, from fashion to electronics. Their data-driven insights help businesses streamline reverse logistics, improve decision-making, and optimize return flows.

ReverseLogix

ReverseLogix is a cloud-based platform that simplifies the management of returns, repairs, and recycling. It integrates seamlessly with e-commerce platforms, allowing businesses to efficiently handle returns and provide customers with smooth experiences throughout the process.

Narvar

Narvar specializes in improving the customer experience by providing a seamless return process. Their platform tracks returns in real time, offering customers visibility into their return journey and making the process more transparent and customer-friendly.

What to Look for in a Solution Provider

When selecting a reverse logistics provider, consider the following:

- Industry-specific features: Ensure the platform caters to your business’s specific needs.

- Scalability: Look for a solution that grows with your business as your return volumes increase.

- Data-driven insights: Choose a provider that offers actionable insights to improve efficiency.

- Customer support: Quality support is essential to help you troubleshoot and make the most of the platform.

- Integration: The solution should integrate seamlessly with your existing systems for maximum efficiency.

Selecting the right provider can significantly improve your reverse logistics strategy and drive cost savings, customer satisfaction, and sustainability.

Future of Reverse Logistics

The future of reverse logistics is driven by key trends that will shape its evolution.

E-commerce returns will continue to grow as online shopping expands. Businesses will need to streamline their return processes using automation and data to handle the increasing volume efficiently and cost-effectively.

The circular economy and sustainability initiatives will play a larger role.

Companies are focusing on reusing, refurbishing, and recycling products to reduce waste and minimize environmental impact. Reverse logistics will be central to these efforts, especially with the growing demand for eco-friendly practices.

On a regional and global level, reverse logistics will adapt to different market needs. While local systems will focus on optimizing domestic returns, global logistics networks will need to address cross-border e-commerce returns, factoring in varied regulations and consumer preferences.

These trends suggest that reverse logistics will continue to evolve with a focus on efficiency, sustainability, and global scalability.

Wrapping Up

I’ve found that reverse logistics isn’t just about saving money anymore. Smarter return systems can build trust, recover value, and make a business stronger in the long run.

From your side as a customer, easy returns feel like part of the journey, not an afterthought. Companies that get this right stand out because they meet your expectations before you even ask.

The tricky part is balancing efficiency, sustainability, and profit. But when businesses manage all three, they see stronger loyalty and smoother operations.

If you want more supply chain insights, I’ve shared practical strategies and case studies in other blogs you might find helpful.