Supply chains are the backbone of global business, connecting suppliers, manufacturers, transporters, and customers.

But with so many steps involved, it’s easy to lose track of what’s happening along the way. When visibility is missing, minor issues can quickly turn into major disruptions.

End-to-end visibility in the supply chain addresses this challenge by providing companies with a comprehensive view of their operations, from sourcing materials to final delivery.

In this blog, I’ll explain what it means, why it’s important, its advantages, and the benefits businesses gain by implementing it.

What is End-to-End Visibility in Supply Chain?

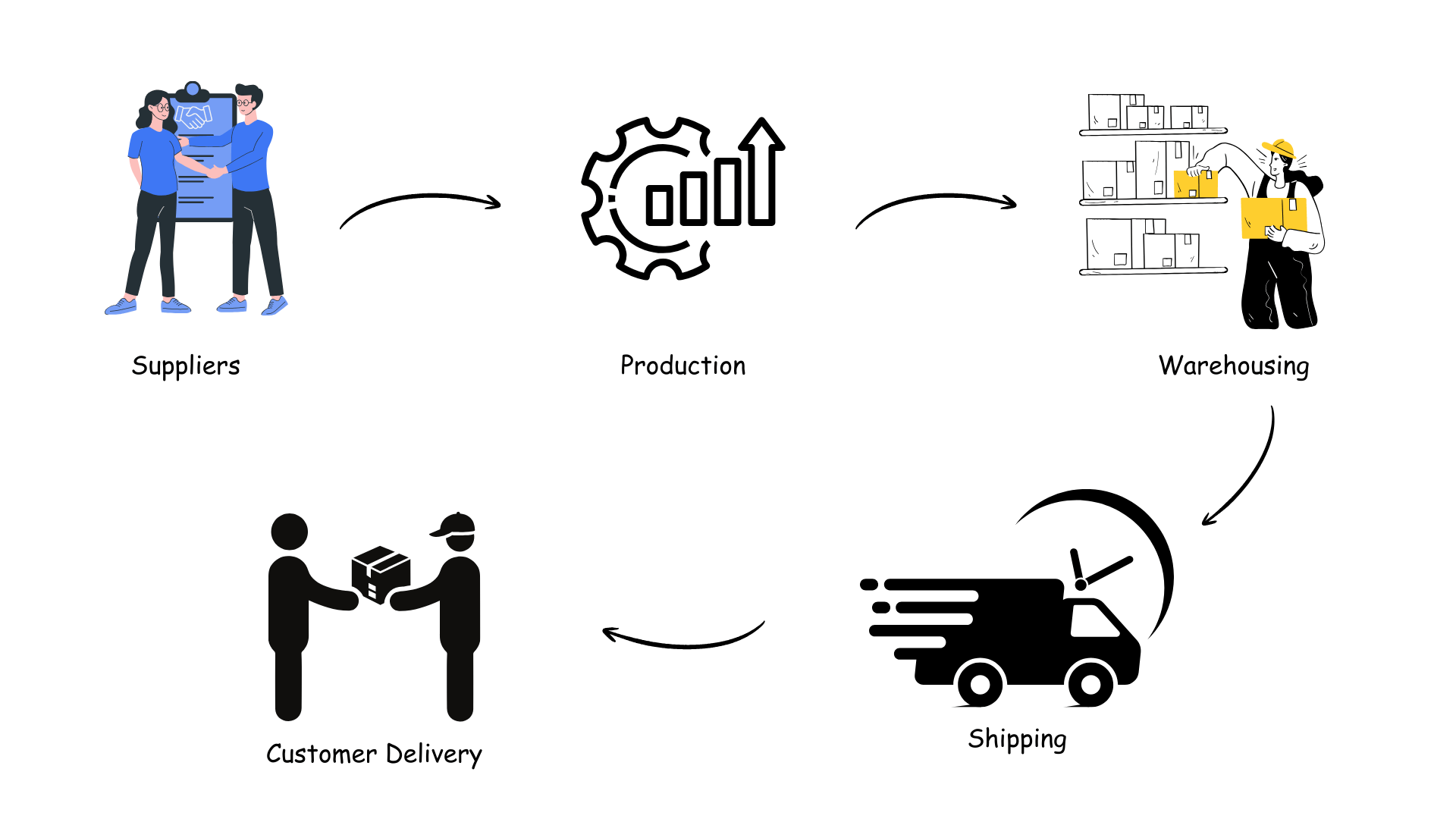

End-to-end visibility in the supply chain means having a real-time view of every stage. It covers suppliers, production, warehousing, shipping, and customer delivery.

Instead of relying on delayed updates or fragmented reports, managers can see the entire process as it unfolds. This clear, real-time view improves supply chain transparency and reduces uncertainty.

Difference From Partial Visibility

Partial visibility gives only a limited view of the supply chain. For example, it might show where goods are once they leave the factory.

The issue is that blind spots remain in other areas. These gaps can hide delays, shortages, or disruptions that affect the entire process.

End-to-end visibility in the supply chain removes those blind spots. It connects data across every stage, so managers see the full picture in real-time.

It’s like comparing one puzzle piece to the completed puzzle. With the whole view, decisions are faster, clearer, and more reliable.

Tools That Enable Visibility

Technology powers visibility. Common tools include:

- Real-time tracking: IoT sensors and GPS to monitor goods at all times.

- Cloud-based supply chain dashboards: Central platforms that collect data from suppliers, carriers, and warehouses.

- Automation & alerts: Notifications when delays, shortages, or risks appear.

- Analytics & AI: Tools that analyze data to predict problems and optimize planning.

- Collaboration portals: Shared systems where all partners access the same updates.

Together, these tools transform raw data into actionable insights, making supply chains more transparent, resilient, and efficient.

Importance of End-to-End Visibility in Supply Chains

Global supply chains are more complex than ever. Without visibility, companies face hidden risks, rising costs, and poor customer trust. Visibility matters because it:

Manages global supply chain complexity: Businesses can monitor operations across different regions in real time.

Meets customer expectations: Accurate updates and on-time delivery build trust and loyalty.

Reduces risks and delays: Early warnings enhance logistics visibility, allowing for the rerouting of shipments before problems escalate.

In short, visibility is no longer optional – it’s essential for competitiveness in today’s fast-changing market.

Advantages and Disadvantages of End-to-End Visibility

Like any business strategy, end-to-end visibility in the supply chain comes with both opportunities and challenges.

Looking at both advantages and disadvantages gives companies a balanced view before committing to a digital supply chain strategy.

| Advantages | Disadvantages |

|---|---|

| No blind spots: Companies can track every stage, reducing surprises and hidden risks. | High cost of technology: Setting up IoT, cloud platforms, and analytics tools requires investment. |

| Better decisions: Real-time data improves planning and forecasting. | Integration challenges: Linking data across suppliers and partners can be complex. |

| Faster response: Early alerts allow quick fixes to disruptions. | Data overload: Too much information may overwhelm teams without proper systems. |

| Customer trust: Accurate updates improve transparency and satisfaction. | Reliance on partners: Visibility depends on suppliers and carriers sharing data openly. |

| Lower costs: Efficiency cuts waste, delays, and duplicate work. | Cybersecurity risks: More data sharing increases exposure to cyber threats. |

| Stronger collaboration: Partners access the same information, boosting teamwork. | Change management issues: Employees and partners may resist new processes or tools. |

On the positive side, it strengthens supply chain visibility, supports supply chain resilience, and improves customer satisfaction in the supply chain.

On the other hand, businesses must consider issues such as high costs, complex system integration, and cybersecurity risks.

Benefits of Implementing End-to-End Visibility in Supply Chains

While advantages help daily operations, benefits are the long-term results businesses enjoy:

1. Lower Operational Costs

End-to-end visibility reduces waste and duplication across the digital supply chain.

For example, when managers see half-empty trucks in real-time, they can combine shipments and reduce fuel and transportation costs.

Visibility also highlights bottlenecks, excess inventory, or inefficiencies that increase expenses. Over time, supply chain monitoring supports major cost reduction in supply chain operations, freeing resources for innovation and growth.

2. Improved Customer Satisfaction

Customers today expect fast, reliable, and transparent service. End-to-end visibility in the supply chain makes this possible.

With logistics visibility, businesses can share accurate delivery updates, prevent errors, and respond quickly to delays.

This level of openness builds customer satisfaction in the supply chain, strengthens loyalty, and improves overall brand reputation. Happy customers often return and recommend the business to others.

3. Stronger Partner Collaboration

Suppliers, carriers, and retailers often struggle with silos that slow down operations.

End-to-end visibility solves this by connecting all parties through supply chain management software and collaboration platforms. Everyone has access to the same real-time data.

This shared information improves teamwork, reduces confusion, and strengthens relationships. It also enhances supply chain resilience, allowing networks to recover quickly from disruptions such as shortages or transport delays.

4. Competitive Edge in the Market

In today’s global supply chain, companies need agility to stay ahead.

With visibility tools, businesses can use supply chain analytics and AI in the supply chain to forecast problems, optimize routes, and adjust production before issues escalate.

This proactive approach supports competitive supply chain strategies, giving businesses an edge over slower competitors. It also improves market reputation and long-term growth potential.

How to Achieve End-to-End Visibility

Companies can build supply chain visibility by:

- Using real-time tracking tools to monitor shipments (supply chain monitoring).

- Investing in digital supply chain platforms, such as supply chain management software, enables unified data management.

- Sharing data with suppliers and partners to remove silos.

- Automating monitoring and reporting with supply chain analytics and AI in the supply chain to react faster.

By taking these steps, businesses move closer to a supply chain that is not just visible but also smarter and more resilient.

Conclusion

End-to-end visibility in supply chains gives businesses control, clarity, and confidence. It transforms supply chains from a source of risk into a source of strength.

By reducing costs, improving customer satisfaction, and enabling better teamwork, visibility is a powerful long-term investment.

Now is the time to act. Start by adopting digital tools, encouraging data sharing, and building toward complete transparency in a step-by-step approach. Embracing a digital supply chain is the best way to future-proof operations.

Want to future-proof your supply chain? Learn about real-time visibility tools and enhance your operations for a stronger, more reliable performance today.

Frequently Asked Questions

Can visibility support sustainability goals?

Yes. It helps track emissions, reduce waste, and plan greener transportation routes.

How does visibility improve compliance?

It ensures accurate record-keeping and facilitates compliance with international trade regulations.

Is visibility helpful for reverse logistics?

Absolutely. It helps track returns, recycling, and repair processes efficiently.