When I think about what keeps businesses running smoothly, warehouse logistics is always near the top of the list.

Every product that comes in has to be received, stored, tracked, and shipped out in a way that keeps costs down and customers satisfied.

That’s where warehouse logistics comes in. It’s the system that ties all those moving parts together.

For companies, understanding warehouse logistics means understanding how to manage space, people, and technology all at once. It’s the link that connects suppliers, retailers, and customers in one continuous flow.

To understand why it matters so much, let’s start with the basics: What it actually is and how it fits into the bigger picture of supply chain management.

What are Warehouse Logistics?

When people talk about warehouse logistics, they’re really talking about everything it takes to move goods smoothly inside a warehouse.

That includes receiving shipments, storing products in the right spots, keeping track of inventory, and making sure orders are picked, packed, and shipped on time.

In simple terms, it’s the system that keeps a warehouse from turning into chaos.

Warehouse logistics isn’t just about what happens within four walls, though. It’s a key link in the bigger supply chain.

If the warehouse runs well, suppliers can deliver on time, retailers can keep shelves stocked, and customers get their orders without delays.

In other words, well-managed logistics warehouses help keep the entire supply chain moving efficiently.

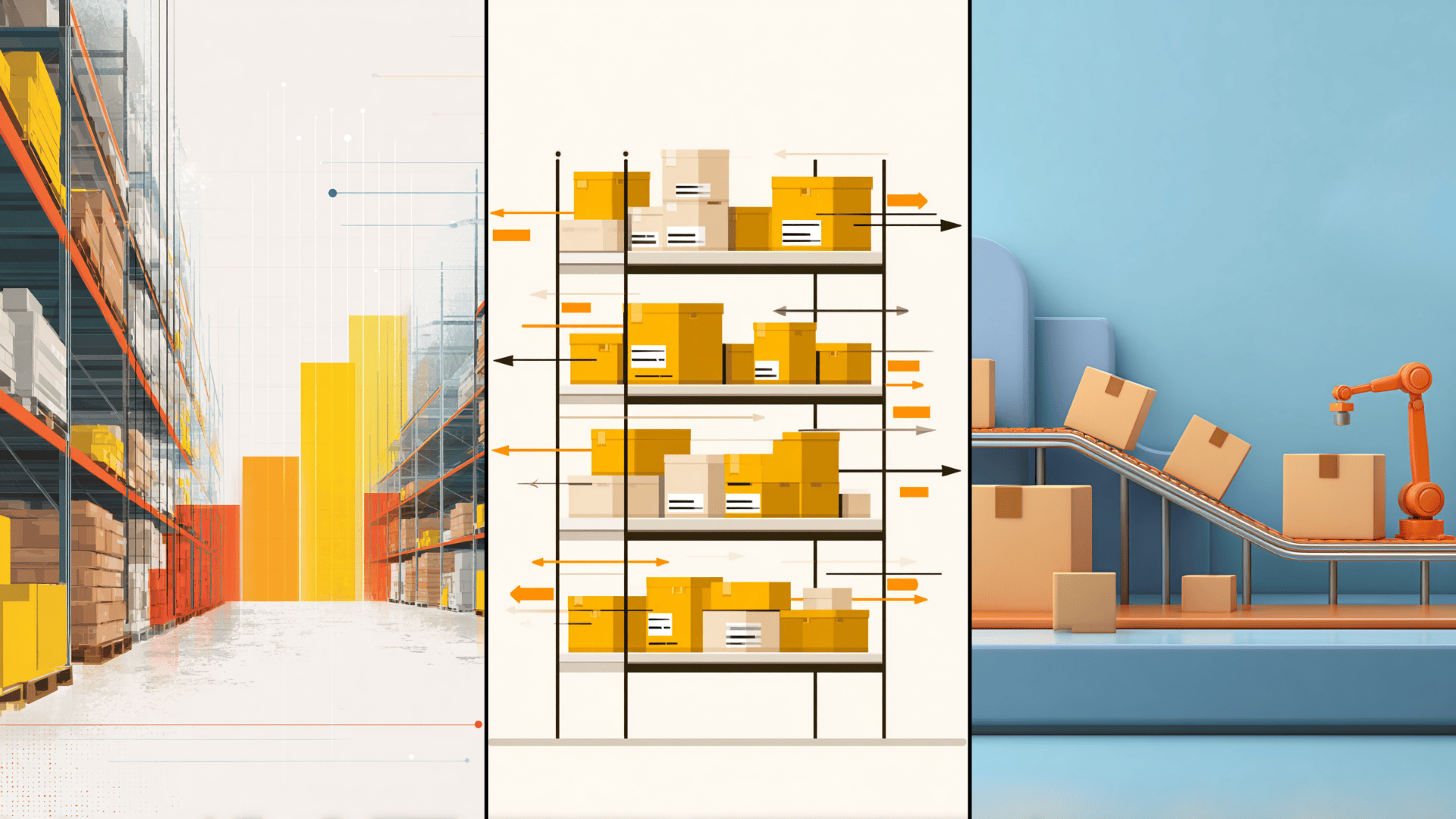

Key Functions of Warehouse Logistics

Warehouse logistics may sound complex, but it really comes down to a set of core functions that keep goods organized and moving.

Each step plays a part in making sure products are handled correctly from the moment they arrive until they leave for delivery.

- Receiving: This is the first step; accepting incoming goods and checking them against purchase orders. Accurate receiving prevents errors and keeps inventory records reliable.

- Putaway: Once items are received, they’re stored in the right location. Efficient putaway makes it easier to find products later and maximizes warehouse space.

- Inventory Management: This involves tracking stock levels, monitoring demand, and running regular counts. Good inventory management avoids stockouts, overstocking, and costly mistakes.

- Picking and Packing: When orders come in, items are picked from storage, packed securely, and prepared for shipment. Speed and accuracy here directly affect customer satisfaction.

- Shipping: The final stage is dispatching orders to their next destination. Smooth shipping ensures customers receive their products on time.

- Storage and Control: Throughout all these steps, products must be stored safely and organized in a way that makes sense. Effective control reduces waste, prevents damage, and keeps operations flowing.

Together, these functions create the backbone of warehouse operations and keep the supply chain running smoothly.

Why Warehouse Logistics Matter: Key Benefits

Warehouses aren’t just storage spaces. The way they’re managed directly affects business success. Strong warehouse logistics control costs, keep goods moving, and help companies meet customer expectations.

Let me give you an in-depth look at some benefits.

Reduced Costs

Efficient warehouse processes help businesses save money. By making better use of space, streamlining labor, and avoiding errors, companies can cut unnecessary expenses and keep operations lean.

They also improve customer satisfaction by ensuring faster and more accurate deliveries.

Improved Efficiency

Well-run warehouses keep products moving without bottlenecks. Accurate inventory records, smart layouts, and reliable systems help businesses meet demand and adjust quickly when order volumes change.

They also reduce stress on workers by making daily tasks smoother and more organized.

Better Customer Satisfaction

From a customer’s point of view, warehouse logistics directly shape their experience. Fast and accurate order fulfillment builds trust, while delays or mistakes create frustration.

Customers may never see the warehouse, but they feel the results every time an order arrives on time and in good condition.

Stronger Supply Chain Performance

Warehouses aren’t just storage; they’re a key link in the supply chain. When logistics are well-managed, suppliers, retailers, and customers are all aligned. This connection makes the entire supply chain more reliable and resilient.

In short, effective warehouse logistics creates a win-win situation. Businesses operate more efficiently while customers enjoy better service and reliability.

Common Challenges in Warehouse Logistics

Even the best-run warehouses face challenges that can slow things down or drive up costs. Below are some of the most common issues businesses deal with:

- Space constraints: As inventory grows, warehouses often run out of room. Poor layouts or inefficient storage can make the problem worse, forcing companies to spend more on extra space or risk slower operations.

- Labor shortages and costs: Finding and keeping skilled workers has become harder and more expensive. High turnover, training needs, and rising wages all add pressure to warehouse budgets while reducing efficiency.

- Errors and inefficiencies: Mistakes like mis-picks, lost inventory, or poor documentation create costly setbacks. Even small errors can ripple across the supply chain, leading to delays and unhappy customers.

- Seasonal and demand fluctuations: Warehouses often face unpredictable spikes in orders during holidays or seasonal changes. Without flexible systems in place, these surges can overwhelm staff and lead to delays or backlogs.

A warehouse that struggles with these challenges can quickly see costs rise and service levels drop. The good news is that with the right strategies in place, most of these issues can be managed before they disrupt operations.

Strategies to Optimize Warehouse Logistics

I know for a fact that the most efficient warehouses aren’t always the biggest; they’re the ones that use smart strategies to keep things moving.

When you combine the right tools with good practices, it saves time, cuts costs, and makes everyone’s job easier.

1. Use of WMS

A Warehouse Management System (WMS) is like the brain of the operation. I’ve noticed that when businesses start using one, accuracy goes up almost immediately.

Real-time tracking, barcode scanning, and automated reports replace guesswork, which means fewer errors and less wasted effort. Even smaller warehouses benefit from a WMS because it takes pressure off manual recordkeeping.

2. Optimized Layout

I’ve walked through warehouses where just rearranging product zones cut picking times in half.

A well-thought-out layout keeps fast-moving items close to packing stations and sets up clear pathways for forklifts or workers on foot. It’s a simple change, but I’ve found it has a huge impact on safety and productivity.

3. FIFO and Inventory Rotation

First-In, First-Out (FIFO) might sound basic, but I’ve seen what happens when it’s ignored: expired stock and wasted money.

Rotating inventory properly keeps goods moving and reduces write-offs. With clear labeling and assigned storage spots, workers don’t have to think twice about which items to pick first.

4. Data-Driven Performance Measurement

Numbers tell the story. Tracking order accuracy, fulfillment times, or even how often stockouts happen helps spot issues before they spiral.

I’ve found that regular check-ins with these metrics guide better decisions, whether that’s hiring more staff or rearranging a workflow.

5. Automation and Robotics

When repetitive work eats up too much time, automation steps in. I’ve seen conveyors, AMRs, and even robotic pickers speed up tasks that used to take hours.

The upfront cost is high, but the payoff shows up in fewer errors, faster turnaround, and smoother handling during busy seasons.

6. Workforce Training and Equipment Investment

At the end of the day, warehouses still run on people. Investing in staff training makes a real difference; workers feel more confident, and mistakes drop.

The same goes for equipment: forklifts, pallet jacks, and safety gear aren’t just tools; they’re what keep people working safely and efficiently.

The Role of Technology in Modern Warehouse Logistics

Technology has changed the way warehouses operate, and I’ve seen the difference firsthand.

Simple tools like barcode scanners and real-time dashboards cut down on errors and give managers better visibility. They may not seem flashy, but they make daily work smoother.

- Warehouse Management Systems (WMS) are now at the core of most facilities. Once a WMS is in place, inventory counts become more reliable, picking mistakes drop, and workers spend less time chasing lost items. It’s one of those upgrades where the impact shows up almost immediately.

- Automation and robotics have also taken on a bigger role. I’ve watched robots and conveyors handle repetitive tasks faster than people ever could. That doesn’t replace workers; it frees them up to focus on jobs that actually need human judgment.

- IoT sensors and AI push things even further. Sensors track storage conditions and equipment use in real time, while AI turns that data into forecasts.

I’ve seen it help predict demand spikes, highlight stock risks, and flag possible delays before they happen. Instead of reacting to problems, warehouses can prepare ahead of time.

Technology doesn’t just speed things up; it makes warehouses more dependable and gives both workers and managers the tools to stay ahead.

Careers in Warehouse Logistics

I’ve seen that warehouse logistics jobs cover more than just moving goods.

A warehouse logistics specialist is one of the most common roles, handling inventory tracking, managing shipments, and keeping daily operations on schedule. Accuracy and organization matter a lot here because even small mistakes can create delays.

The skills that stand out most are knowing how to use systems like a WMS, being comfortable with data, and coordinating with both staff and equipment.

I’ve noticed that workers who invest in certifications or training often move into better-paying or more technical positions.

This field is still growing as e-commerce and automation expand. Pay depends on location and experience, but warehouses that rely heavily on technology usually pay more for staff who can manage and optimize those systems.

Wrapping Up

Warehouse logistics is what keeps goods moving smoothly through the supply chain. A well-run warehouse lowers costs, reduces mistakes, and improves customer satisfaction by making sure orders arrive when they should.

The key is managing core functions like receiving, storage, and shipping while using tools such as WMS, automation, and data insights to stay efficient.

Challenges like limited space, labor costs, and seasonal spikes will always be part of the job, but with the right strategies, they don’t have to slow things down.

If you found this useful, take a look at my other blogs on logistics and supply chain management. You’ll pick up more practical ideas to make warehouse operations run even better.