When I first started learning about global trade, I kept hearing the term ISO container and wondered what made it so important.

Simply put, an ISO container is a standardized shipping container designed to move goods safely across ships, trucks, and trains.

Because these containers adhere to strict ISO container specifications, they fit perfectly into the global transport system.

In this guide, I’ll explain what ISO containers are, their common uses, the types of ISO containers, and their key dimensions and specifications.

By the end, you’ll know why they are the backbone of modern shipping.

What is an ISO Container?

An ISO container is a standardized shipping container designed according to the rules of the International Organization for Standardization (ISO).

These containers come in set dimensions, usually 20ft, 40ft, or 45ft, and are designed to fit perfectly on ships, trucks, and trains.

Because they adhere to the same specifications worldwide, they facilitate global trade, making it faster, safer, and more cost-effective.

ISO containers are used to transport a wide range of cargo, including dry goods, liquids, refrigerated products, and oversized equipment.

Their durability, safety approvals, and clear markings ensure cargo is protected and easily traceable. Simply put, ISO containers are the backbone of modern international shipping and storage.

Common Uses of ISO Containers

ISO containers are used far beyond just ocean shipping. Their strength, standard sizes, and safety features make them useful in many industries.

1. In Global Shipping and Trade

- Transport goods across sea, road, and rail with ease.

- Fit perfectly into ships, trucks, and trains without repacking.

- Keep cargo safe from weather and damage during long journeys.

2. For Storage and Warehousing

- Provide secure, temporary storage for businesses or individuals.

- Can be placed at construction sites, warehouses, or farms.

- Protect goods from theft, pests, and environmental factors.

3. Specialized Applications in Industries

- Refrigerated containers store food, medicine, or chemicals at safe temperatures.

- Tank containers safely carry fuel, gas, or other liquids.

- Modified containers serve as mobile offices, workshops, or even homes.

These uses demonstrate that ISO containers are not just for shipping—they are versatile solutions for storage, transportation, and even creative repurposing.

Types of ISO Containers

ISO containers come in different types, each made for specific cargo needs. From dry goods to liquids and oversized items, these variations make global shipping more flexible and reliable.

1. Dry Storage Containers (Standard Containers)

These are the most common ISO containers, used for general cargo, such as boxes, pallets, and equipment. They come in 20ft, 40ft, and 45ft sizes and protect goods from weather and damage.

Businesses prefer them because they are widely available and can be stacked easily for efficient transport.

2. Refrigerated Containers (Reefer)

Reefer containers are designed to maintain the controlled temperatures required for goods such as food, medicine, and chemicals. They feature built-in cooling systems, ensuring freshness during long-distance shipping.

Many models can maintain temperatures as low as –30°C, making them essential for sensitive cargo.

3. Open Top Containers

These containers have a removable roof, making them ideal for oversized cargo such as timber, pipes, or machinery that can’t fit through standard doors.

Loading is done with cranes from above, which makes handling heavy or awkwardly shaped cargo much easier.

4. Flat Rack Containers

Flat racks are constructed with collapsible sides or no sides at all, making them ideal for handling heavy loads such as vehicles, construction materials, and industrial equipment.

Their open design provides flexibility, and some even come with end walls for extra support.

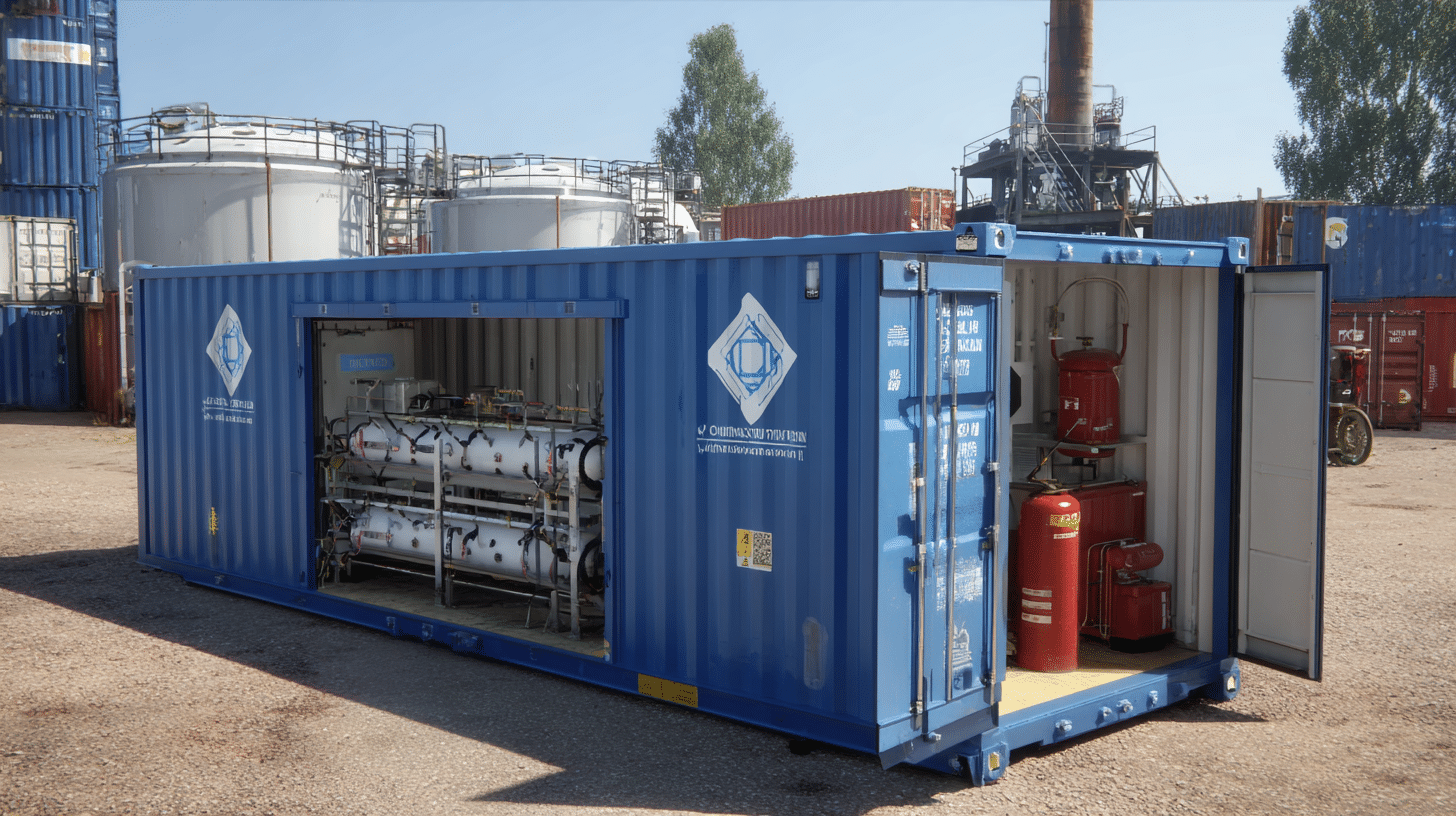

5. Shipping ISO Tank Containers

Made for transporting liquids, gases, and chemicals, tank containers are cylindrical tanks mounted inside a frame.

They’re safe, durable, and follow strict ISO container specifications. Since they are designed for multi-modal transport, they reduce the need for transferring liquids between tanks.

6. High Cube Containers

Similar to dry storage containers but taller by approximately one foot, high-cube containers provide extra space for lightweight yet bulky items, such as furniture or textiles.

Their additional height makes them popular in industries that ship large volumes of low-weight goods.

7. Specialized and Custom Containers

These are modified containers designed for unique uses, such as mobile offices, workshops, homes, or specialized industry needs.

They showcase the adaptability of ISO containers beyond their use in shipping. Many companies repurpose them for eco-friendly building projects or pop-up shops.

ISO Container Dimensions and Specifications

Understanding the dimensions and specifications of ISO containers is crucial for planning shipments, as it enables businesses to match the right container with their cargo.

| Container Type | Length (External) | Width (External) | Height (External) | Capacity / Notes |

|---|---|---|---|---|

| 20ft Standard ISO Container | 20 ft (6.06 m) | 8 ft (2.44 m) | 8.6 ft (2.59 m) | Holds ~33 cubic meters, max payload ~28,000 kg |

| 40ft Standard ISO Container | 40 ft (12.19 m) | 8 ft (2.44 m) | 8.6 ft (2.59 m) | Holds ~67 cubic meters, max payload ~28,000 kg |

| 45ft Standard ISO Container | 45 ft (13.7 m) | 8 ft (2.44 m) | 8.6 ft (2.59 m) | Extra length for high-volume cargo |

| 40ft High Cube Container | 40 ft (12.19 m) | 8 ft (2.44 m) | 9.6 ft (2.89 m) | Holds ~76 cubic meters, ideal for bulky items |

| Reefer Container (40ft) | 40 ft (12.19 m) | 8 ft (2.44 m) | 8.6 ft (2.59 m) | Temperature: controlled, typically –30°C to +30°C |

| Tank Container | Standard frame size | 8 ft (2.44 m) | 8.6 ft (2.59 m) | Built for liquids/gases, capacity ~24,000 liters |

Key Points to Know:

- Standard widths are always 8 ft, making stacking and transport easier.

- High cube containers add an extra foot of height for bulky loads.

- Payload capacity may vary slightly depending on design and manufacturer.

- ISO ensures dimensions are consistent across all regions and shipping lines.

By knowing these standard ISO container sizes and specifications, shippers can avoid delays, maximize space utilization, and ensure safe and cost-effective cargo handling.

ISO Container: Identification & Markings

Every ISO container is clearly marked to facilitate easy tracking, ensure safe use, and prepare it for international shipping. Here’s what they include:

Container Numbers and Codes

Each container has an 11-character number (e.g., ABCU1234567).

- Owner Code (3 letters): Shows who owns the container.

- Category Identifier (1 letter): Usually “U” for freight containers.

- Serial Number (6 digits): Unique to that container.

- Check Digit (1 number): Confirms the code is valid.

CSC Plate and Safety Approvals

A CSC plate (Convention for Safe Containers) is fixed on every container. It lists:

- Date of manufacture

- Container type and size

- Maximum gross weight and payload

- Safety approval details

ISO Markings and Their Meaning

- Weight Markings: Show max gross weight, tare weight (empty), and net weight.

- Size and Type Code: A 4-character code that explains container type (e.g., 45G1 = 40ft High Cube Dry).

- Operational Marks: Instructions like “MAX GROSS” or hazard labels.

- Company Logos/IDs: For shipping line or owner identification.

Why it matters: These markings make containers traceable, safe, and globally accepted, so goods move smoothly across ships, trucks, and trains.

Advantages of Using ISO Containers

When it comes to shipping and logistics, efficiency and safety are top priorities. ISO containers have become the global standard because they simplify, enhance safety, and reduce the cost of transporting goods.

- Efficiency in Transport: Standard sizes mean containers fit perfectly on ships, trucks, and trains, reducing handling time.

- Cost Savings: Lower loading and unloading costs make international shipping more affordable.

- Safety and Protection: Strong steel walls keep cargo safe from weather, theft, and damage.

- Versatility: Can carry everything from dry goods to liquids, frozen food, and even oversized equipment.

- Global Acceptance: Standardized by ISO, they are recognized worldwide, making cross-border shipping smoother.

- Reusability and Durability: Built to last for many years, containers can be reused for transportation or converted into storage facilities and buildings.

Their uniform design enables businesses to transport products across seas, railways, and highways with ease, while ensuring durability and protection.

Conclusion

ISO containers are the foundation of global trade, offering standardized sizes, strong construction, and versatile uses.

From dry storage and reefers to tank and high cube containers, each type serves a unique purpose.

Their clear markings, safety approvals, and consistent specifications make shipping efficient, cost-effective, and secure worldwide.

By understanding the types, dimensions, and advantages of ISO containers, businesses and individuals can select the most suitable option for their cargo needs.

Simply put, ISO containers ensure goods are transported safely and smoothly across the world.

Ready to choose the right ISO container? Start planning your shipments with confidence and see how these containers simplify global trade.