I’ve always found it interesting how little we notice the ships that quietly shape everyday life. While container ships often steal the spotlight, a car carrier ship plays just as big a role in global trade.

These vessels don’t just move cars; they connect factories, ports, and markets across continents. Without them, the flow of vehicles into showrooms and streets worldwide would slow to a crawl.

You may never see one up close, but the way they’re designed and operated is worth a closer look. So, let’s start with the basics.

What is a Car Carrier Ship?

A car carrier is built to move cars and other vehicles across the sea. These ships use a system called RORO, short for roll-on/roll-off. That means vehicles roll onto the ship at the starting port and roll off again at the destination, instead of being lifted by cranes.

There are two main types of car carrier ships you’ll hear about:

- PCC (Pure Car Carrier): Made to carry only cars.

- PCTC (Pure Car and Truck Carrier): Built for cars, trucks, buses, and even heavy equipment.

The design of these ships is pretty unique. You’ll find:

- Ramps so cars can drive on and off quickly.

- Multiple decks that stack vehicles like a floating garage.

- Lashing systems to secure each car in place so nothing moves during rough seas.

When I first learned about these ships, I was surprised by how simple the idea sounds, but how massive the scale really is. If you think of a parking garage on water, you’re on the right track.

How Car Carrier Ships Work

Car ships may look like giant floating boxes, but the way they work is pretty clever. Everything is designed to move thousands of cars safely and quickly from one place to another.

Loading and Unloading Process

Cars use ramps to drive directly onto the ship, almost like parking in a massive garage. Once inside, crew members guide each car to its deck and parking spot.

At the destination port, the process is reversed, vehicles roll right back off. I’ve found it’s one of the fastest ways to load so many cars at once.

Cargo Security Measures

Once a car is parked, it has to be secured for the entire trip. Crews use strong lashing straps and clamps to lock each vehicle in place. These systems keep cars steady, even when the sea gets rough.

I’ve seen this step being treated with extra care because one loose vehicle could cause serious damage.

Crew Operations and Daily Life

Life on board isn’t just about moving cars. The crew checks lashings, monitors each deck, and keeps track of navigation. Their daily routine is a mix of safety checks and ship operations. From what I know, it’s steady, hard work that makes long voyages possible.

Largest Car Carrier Ships in the World

Some car carriers are so big they almost feel unreal. These record-breaking ships move thousands of vehicles in one trip, making global auto trade possible on a massive scale.

One of the biggest names right now is the BYD Shenzhen. It’s more than 700 feet long and can carry up to 9,200 cars at once.

Another giant, the Trapper, travels routes as long as 38,000 km, carrying around 8,500 cars plus heavy cargo.

When I first read about these ships, I was amazed at how much they can handle in a single journey.

Not every ship is the same size, but most large carriers can move between 5,000 and 9,000 cars. Some are also built to handle heavy trucks, buses, and construction machines.

To picture it, think of several sports stadiums filled with vehicles; stacked, organized, and locked into place. That’s the scale we’re talking about.

Shipbuilders are already working on even larger and more efficient designs. Many of these projects focus on using cleaner fuels and smarter layouts to carry more vehicles with less impact on the environment.

It’s a sign that car carriers will keep getting bigger, but also greener.

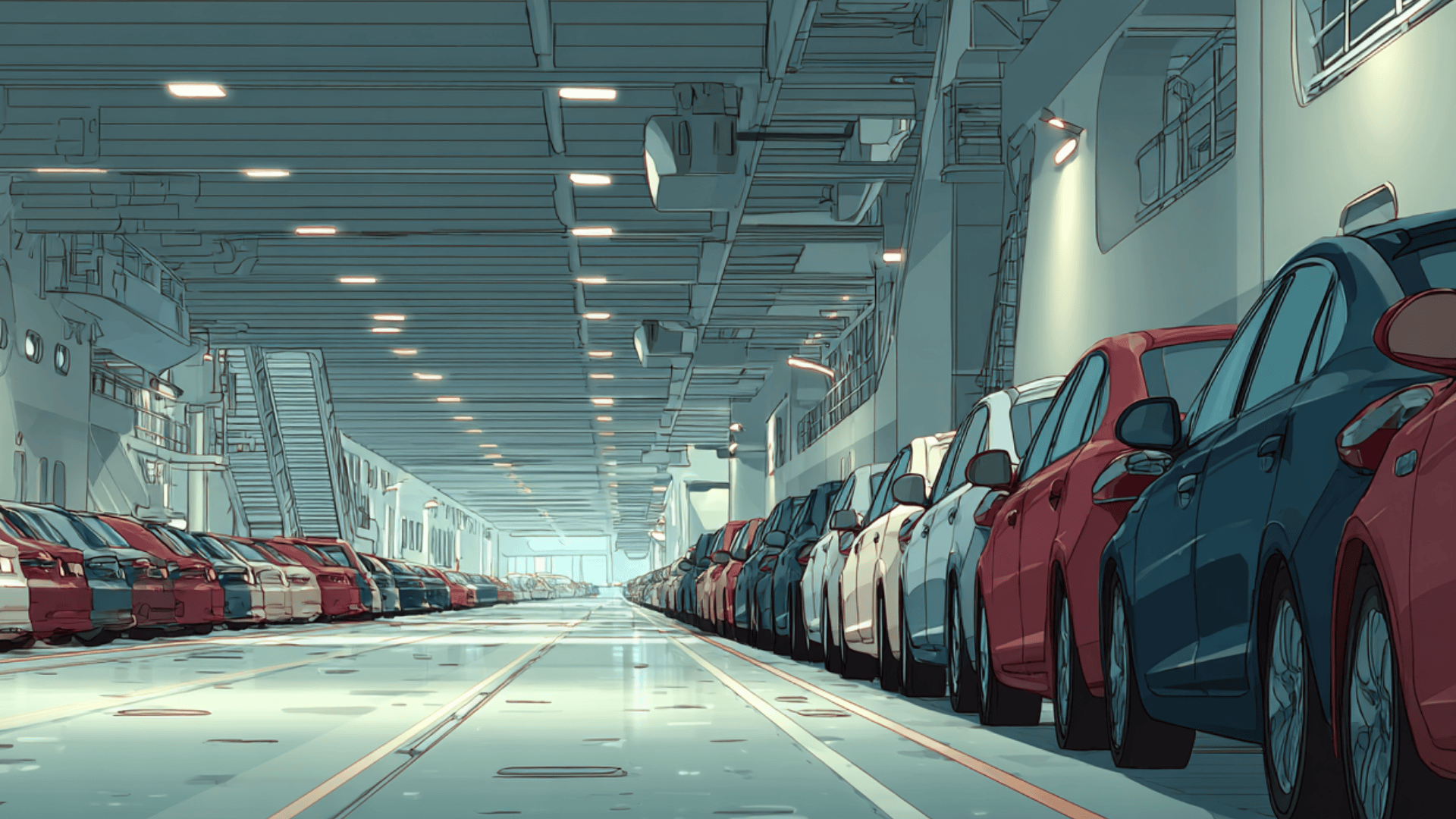

Inside a Car Carrier Ship

If you’ve ever wondered what the inside of a car carrier looks like, it’s a mix of practicality and scale. Walking through one feels like stepping into a massive parking garage at sea, designed for both efficiency and safety.

1. Touring the Interior

The decks stretch for hundreds of feet, stacked one above another. Ramps connect each level so vehicles can drive between them.

Some decks are even adjustable, letting the crew change the height to fit taller trucks or buses. I’ve found the space feels tight but highly organized; every inch has a purpose.

2. Safety Challenges on Board

Packing thousands of cars close together comes with real risks. Fires are the biggest concern, since aisles are narrow and exits are limited.

Crews prepare with alarms, fire-resistant materials, and specialized firefighting gear. It’s one of those challenges you don’t see from the outside but plays a huge role in ship design.

3. Technology and Systems Onboard

Behind the scenes, these ships run on smart systems. Powerful ventilation clears exhaust from the decks, while lighting and sensors help monitor every level.

Navigation equipment on the bridge keeps the ship on course, and automated alarms warn crews of any issues. From what I’ve seen, it’s a constant balance of machinery and human attention.

4. Unique Design Features

Car carriers aren’t just big boxes. Many have decks that can shift in height, giant watertight doors, and ramps strong enough to handle heavy machinery.

Ventilation fans are built into almost every level to manage heat and exhaust. These details might not stand out at first glance, but they’re what make the ships work smoothly.

Car Carrier Ships in Global Trade

Car carrier ships are the link that keeps the auto industry moving. Without them, cars built in one country wouldn’t reach buyers halfway across the world.

Most vehicles are built far from where they’re sold. Car carriers bridge that gap by moving thousands of cars at once from factories to foreign markets.

I know for a fact how this step cuts costs and keeps new cars arriving at dealerships on time. It’s the reason you can buy a Japanese sedan or a German SUV almost anywhere.

Some of the biggest operators include:

- NYK Line: Japan-based, one of the largest car carrier fleets in the world.

- Wallenius Wilhelmsen: Norway’s shipping giant with a global network.

- K Line: Known for transporting both cars and heavy machinery.

- MOL (Mitsui O.S.K. Lines): Runs large modern carriers across key trade routes.

And here’s what that looks like in practice:

A ship leaves Germany loaded with thousands of luxury cars, heading toward Australia. The trip covers nearly 38,000 km and takes weeks to complete. From Japan, similar vessels sail across the Pacific to the U.S., carrying sedans, hybrids, and electric cars.

Every car that rolls off the port has already traveled further than most people will in a lifetime.

Costs and Economics of Car Carrier Ships

Car carrier ships aren’t just huge in size; they’re massive investments. The money side of things can be surprising, whether you’re talking about building one, running it, or simply shipping a single car.

How Much Does It Cost to Build or Buy One?

A smaller carrier that holds around 1,000 cars usually costs between $20 million and $30 million.

Larger ships that carry 8,000 to 9,000 cars can run from $50 million up to well over $100 million, especially if they’re built with modern, fuel-efficient systems.

The bigger the ship, the higher the upfront price, but also the more cost-effective it becomes per vehicle.

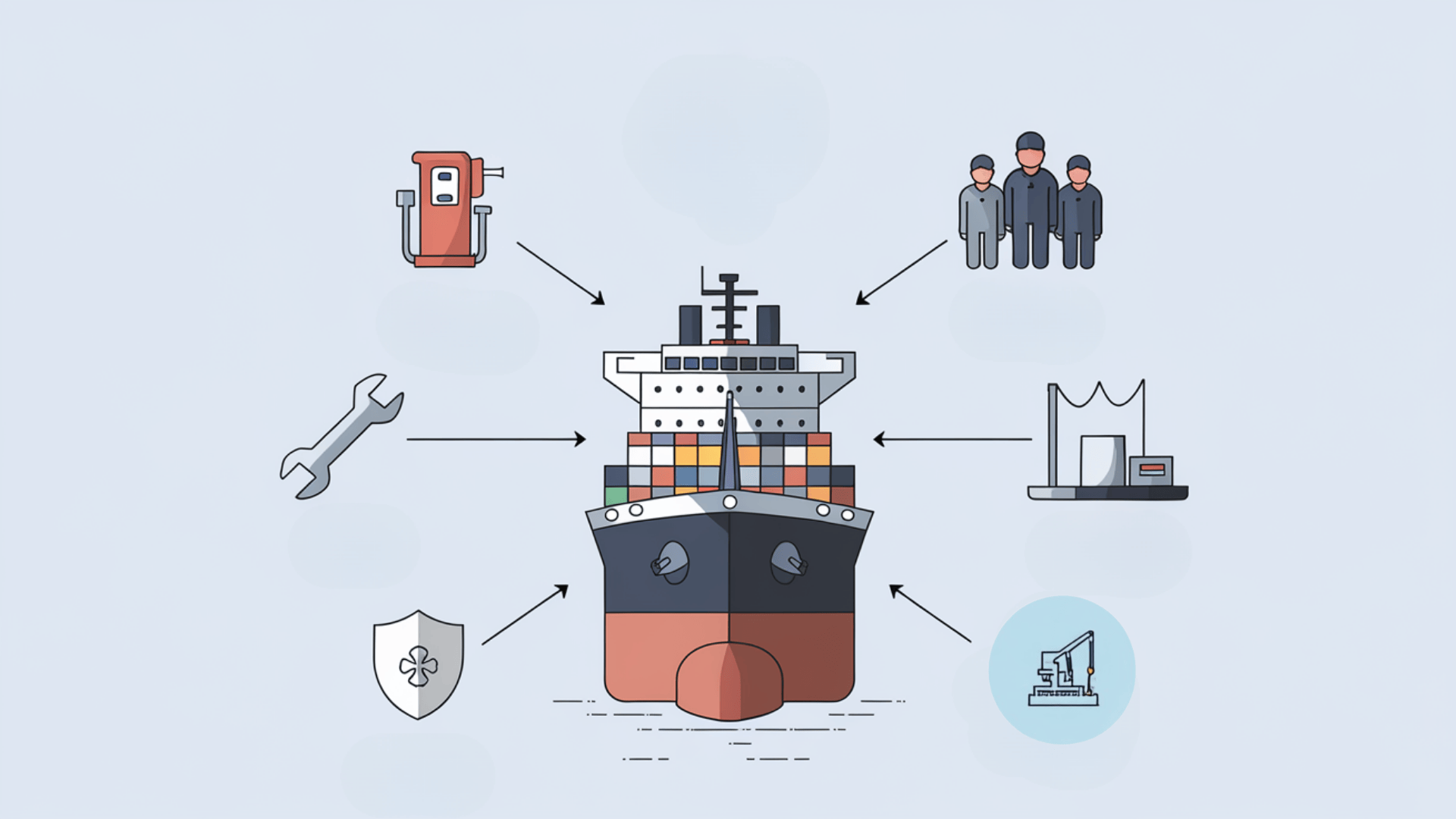

What About Operating Costs?

Running one of these ships every day adds up fast. Chartering a large car carrier can cost around $115,000 per day, and that’s before you even consider other expenses like:

- Fuel: the single largest cost, especially on long routes.

- Crew wages: dozens of people working weeks at sea.

- Maintenance and repairs: keeping ramps, engines, and decks in working order.

- Port fees and insurance: every stop along the way comes with extra charges.

All in, a single voyage can cost hundreds of thousands of dollars to operate.

So, How Much to Ship One Car?

If you’re just moving a personal car overseas, the price usually falls between $700 and $1,200 on standard routes. For larger vehicles like trucks or heavy machinery, it’s more in the range of $2,000 to $5,000, depending on size, distance, and port fees.

In the end, the economics come down to scale. It’s expensive to build and run these ships, but by carrying thousands of cars at once, the cost per vehicle stays manageable. That’s why they’re such a vital piece of the global auto industry.

Sustainability and Innovation in Carrier Ships

Car carrier ships are getting bigger, but they’re also becoming cleaner. Shipping companies know that cutting emissions matters, and new designs show just how fast the industry is changing.

Cleaner Fuels

Many of the latest carriers run on LNG (liquefied natural gas) instead of heavy oil. LNG burns cleaner, cutting down on greenhouse gases and air pollution.

Some builders are also testing biofuels, hybrid systems, and even early versions of electric support power. It’s a shift you wouldn’t have seen a decade ago.

Smarter Efficiency

New carriers are built with sharper hull designs, better propellers, and improved ventilation systems. These tweaks don’t just save fuel, they also make voyages faster and safer. Even the way decks are arranged now helps load and unload vehicles with less wasted time.

Looking Ahead

The future is all about green car carriers. Projects are already in the works for ships powered by ammonia, hydrogen, or wind-assisted technology like massive sails.

The goal is simple: move more cars with less fuel, fewer emissions, and smarter technology.

If these designs become standard, the next generation of carriers will be just as focused on the environment as they are on size.

Risks and Incidents

Even with all the planning that goes into them, car carrier ships face serious risks at sea. Here are some of the biggest ones to know about:

- Accidents and collisions: Their tall, box-shaped design makes maneuvering difficult in rough weather or crowded ports. When accidents occur, the impact can damage both the ship and thousands of vehicles.

- Sinkings: If stability is lost, these vessels can capsize quickly. A single sinking may cause the loss of an entire cargo load, costing millions in vehicles and equipment.

- Fire hazards: Vehicles packed close together create the perfect environment for fires to spread. Battery faults, fuel leaks, or electrical issues can spark blazes that are hard to contain.

- Cargo damage: Even without accidents, heavy seas can shift vehicles inside the decks. Strong lashings help, but dents, scratches, and mechanical damage are still a risk during long voyages.

- Crew safety: Emergencies like capsizing or fires leave little room or time for evacuation. Crew members rely on strict training and drills to handle dangerous situations quickly and effectively.

- Insurance and compliance: Because of these risks, operators face high insurance costs. They must also follow strict international rules and inspections to keep ships certified and safe for global trade.

While the risks are real, carriers continue to improve safety systems and crew training. Each lesson learned from past incidents helps make future voyages safer.

Wrapping Up

When I think about car carriers, I don’t just see giant vessels at sea. I see the hidden systems that keep everyday life moving. Bringing cars, trucks, and even machinery from one side of the world to the other.

What really stands out is how these ships are changing: becoming safer, more efficient, and cleaner as new fuels and smarter designs take hold.

It’s a reminder that global trade is not just about scale, but also about responsibility and innovation.

Curious to learn more? Check out my other blogs for deeper looks at global transport, shipping trends, and the future of logistics.