I’ve always been curious about how products move so smoothly from factories to store shelves or even straight to my doorstep.

That curiosity led me to learn more about warehousing and distribution, and I realized just how important these two parts of the supply chain really are.

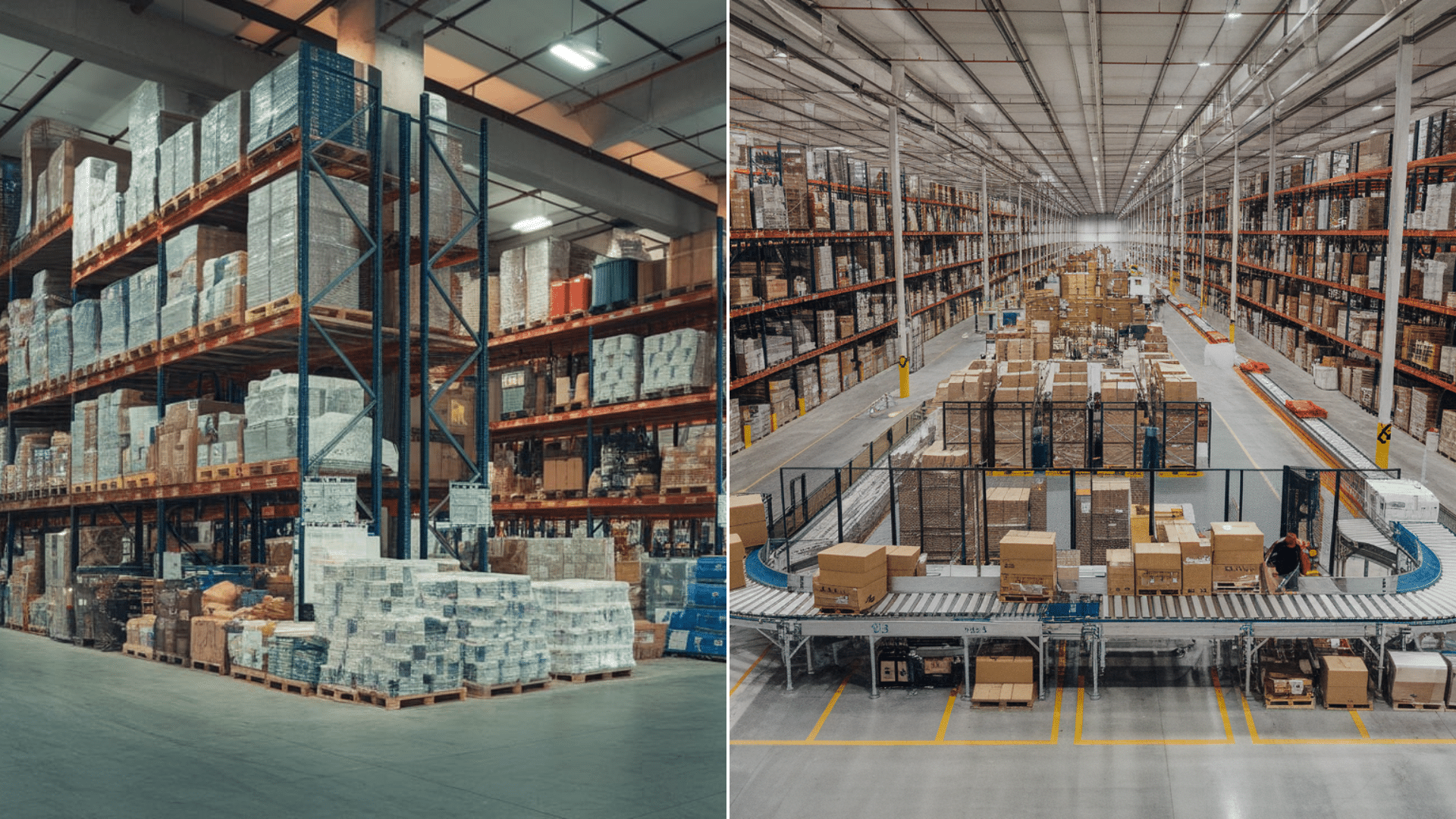

A warehouse is mainly about storing goods safely until they’re needed, while a distribution center focuses on getting products moving quickly to the next stop.

Both play very different but connected roles, and understanding the difference can help businesses manage inventory, cut costs, and serve customers faster.

In this guide, I’ll break down what warehousing and distribution mean, how they work, and why they matter so much today.

Understanding Warehousing and Distribution

Let’s start by breaking down what warehousing really means and the role it plays in moving products.

What is Warehousing?

Warehousing is the process of storing goods in a safe, organized space until they are needed for sale, distribution, or use. Think of it as a holding area in the supply chain where products are kept in bulk before moving further downstream.

A warehouse is designed to protect items from damage, theft, or spoilage while keeping them easy to track and access.

Inside a warehouse, activities include receiving shipments, labeling, putting products away, managing inventory levels, and preparing items for later distribution.

Unlike a distribution center, which focuses on fast movement, warehousing is more about long-term storage and careful control of stock. It ensures that businesses always have the right products available when demand rises.

What is a Distribution Center?

A distribution center is a facility designed to quickly move products from suppliers to retailers, wholesalers, or directly to customers.

Unlike a warehouse, which focuses on long-term storage, a distribution center is all about speed and efficiency. Goods usually don’t stay there very long – they’re received, sorted, and shipped out as fast as possible.

Inside a distribution center, you’ll see activities like cross-docking, picking, packing, and order consolidation. These steps help businesses get products to the right place at the right time.

Distribution centers are often located near major markets or transportation hubs, making them a key link in the supply chain. Their main goal is to keep goods flowing smoothly so customers get what they need quickly.

Warehousing and Distribution: Key Differences

When I first learned about supply chains, I thought warehouses and distribution centers were the same. In reality, they serve very different purposes.

Warehousing is focused on storage and inventory management, while the distribution center’s meaning is tied to speed – getting products in and out quickly to meet customer demand.

Understanding these differences helps businesses decide which setup they need or how to balance both for smoother operations.

| Feature | Warehouse Distribution | Distribution Center |

|---|---|---|

| Main Purpose | Long-term storage and inventory control | Rapid movement and order fulfillment |

| Storage Time | Weeks to months | Hours to days |

| Activities | Receiving, storing, and cycle counting | Picking, packing, cross-docking, shipping |

| Role in Supply Chain | Acts as a buffer to maintain stock levels | Pushes goods quickly to the next stop/customers |

| Best For | Bulk storage, seasonal stock, safety reserves | Retail replenishment, ecommerce, fast orders |

Both warehouses and distribution centers play a vital role in supply chains. By knowing how they differ, you can make smarter decisions about storage, speed, and customer service.

Warehousing and Distribution Processes: From Receiving to Shipping

Every product goes through a clear set of steps before reaching its final destination. These processes keep inventory organized, orders accurate, and deliveries on time.

- Receiving and Inbound Handling: Goods are unloaded, checked against purchase orders, inspected for damage, and entered into inventory systems.

- Storage and Inventory Management: Products are placed in racks, bins, or pallets and tracked through systems like WMS for easy access and control.

- Picking and Packing: Orders are picked using batch, zone, or wave methods, then packed securely to prevent damage during transit.

- Shipping and Dispatch: Orders are labeled, consolidated, and loaded for carriers to ensure timely and accurate delivery.

These steps work together to keep operations smooth and help businesses deliver products on time with fewer errors.

Warehousing and Distribution Models

There are different models businesses can use depending on their size, budget, and supply chain needs. Each comes with its own benefits and trade-offs.

1. Private Warehousing

Private warehousing means a company owns and operates its own storage facility. This model offers complete control over processes, inventory, and security.

It’s ideal for large businesses with steady demand and high volumes.

The main drawback is cost – building or leasing space, staffing, and maintaining systems can be expensive. Still, private warehouses allow companies to design layouts and workflows that fit their exact needs.

2. Public Warehousing

Public warehouses are shared facilities where companies rent space for short- or long-term storage.

They are flexible, cost-effective, and especially helpful for small businesses or those with seasonal demand. Because fees are usually based on the amount of space or time used, costs scale with need

The trade-off is less control, since multiple clients share the same facility and operations are run by the provider.

3. Contract Warehousing

Contract warehousing is a middle ground between private and public models. A business partners with a warehouse operator under a long-term agreement.

This setup gives more control and customization compared to public warehousing, but without the full cost of ownership.

Contracts can cover staffing, equipment, and service levels, making it reliable for companies that need stability and scalability.

4. Third-Party Logistics (3PL) Warehousing

Many companies choose 3PL providers to handle both warehousing and distribution. A 3PL offers storage, order fulfillment, shipping, and sometimes even returns.

This model reduces the burden on businesses and allows them to tap into established networks and technology.

The trade-off is dependence on the provider, but for many, the efficiency and expertise outweigh the risks.

Warehousing and Distribution Layouts & Flow

The layout of a facility shapes how goods move from the moment they arrive until they leave. A smart design improves efficiency, reduces handling time, and cuts costs.

Classic Warehouse Layout

- Receiving Area: Designed for unloading trucks and checking shipments.

- Storage Zones: Pallet racks, shelves, or bins arranged for easy access.

- Picking Areas: Forward-pick sections for fast-moving items.

- Packing Stations: Workspaces for preparing orders securely.

- Shipping Docks: Outbound staging for loading trucks.

Distribution Center Flow

- Cross-Docking: Goods move directly from inbound to outbound with little storage.

- Flow-Through Handling: Items pass quickly through pick and pack areas.

- Merge-in-Transit: Combines shipments from multiple suppliers into one order.

- Staging Areas: Organizes outbound loads by carrier or route.

- Rapid Dispatch: Ensures products leave on time to meet delivery promises.

Technology and KPIs in Warehousing and Distribution

The right technology helps warehouses and distribution centers run smoothly, and KPIs (key performance indicators) show if those tools are delivering results.

Core Systems: WMS, TMS, OMS

| System | Full Form | Main Function | Key Benefit |

|---|---|---|---|

| WMS | Warehouse Management System | Tracks inventory, manages storage locations, and directs order picking. | Improves inventory accuracy and picking efficiency. |

| TMS | Transportation Management System | Plans, executes, and monitors shipments across carriers. | Ensures timely deliveries and reduces transport costs. |

| OMS | Order Management System | Connects sales channels with warehouse operations to process customer orders. | Provides seamless order flow and better customer experience. |

These systems work together to create a clear flow from receiving to final delivery.

Automation & Robotics

Scanners make check-ins and check-outs faster by reducing manual data entry, while conveyors cut down on heavy lifting and keep orders moving smoothly through the warehouse.

AMRs (autonomous mobile robots) take automation a step further by handling tasks like picking and replenishment with speed and precision.

By introducing automation in the right areas, warehouses and distribution centers can process more orders accurately while keeping operating costs under control.

Data, Dashboards, and KPIs

Technology generates real-time data, and dashboards make it easy to monitor performance. Common KPIs include:

- Accuracy & Speed: Inventory accuracy, pick accuracy, order cycle time.

- Throughput & Utilization: Lines picked per hour, dock-to-stock time, space use.

- Service & Cost: On-time in-full (OTIF), cost per order, cost per line.

By combining technology with measurable KPIs, businesses can spot inefficiencies, improve processes, and deliver a better customer experience.

Cost Drivers and Network Strategy

The cost of warehousing and distribution comes from daily operations and the way the overall network is set up. Here’s a clear breakdown:

| Area | Key Drivers of Cost | Ways to Reduce Costs | Network Strategy Impact |

|---|---|---|---|

| Space | Rent, utilities, racking, storage equipment | Optimize layout, share space with 3PL | Choose locations with affordable property values |

| Labor | Wages, training, turnover | Use automation, improve workflows | Locate in regions with reliable labor supply |

| Handling | Equipment use, packaging, and maintenance | Better slotting, pick-path design | Standardize handling processes across sites |

| Transportation | Fuel, carrier rates, and last-mile delivery | Cross-dock fast movers, negotiate with carriers | Position DCs near customers and transport hubs |

| Growth & Scalability | Expanding storage and distribution capacity | Phase expansion with demand, use 3PL to start | Add new nodes or split DCs vs. FCs as volumes grow |

By balancing these cost drivers with smart network design, businesses can cut expenses while keeping service levels high.

Conclusion

Warehousing and distribution are the backbone of supply chains, and knowing how they work together helps businesses save money and serve customers better.

The biggest costs usually come from labor and transportation, but with the right processes, technology, and network strategy, these expenses can be managed more effectively.

Designing a smart layout, using automation where it makes sense, and tracking KPIs all play a big role in boosting efficiency.

I’ve seen how even small changes, like better slotting or locating facilities closer to customers, can make a big difference.

For more practical insights on logistics, supply chains, and distribution strategies, read my other blogs for advice you can apply right away.