When I first heard the term cross-docking, it seemed more complicated than it really is. In reality, it’s just a method of moving products through a warehouse quickly without keeping them in storage for long.

Instead of sitting on shelves, goods are unloaded from an inbound truck and loaded right onto an outbound truck headed to their next destination.

This method is used in many industries, from retail to food distribution, because it helps save time and money.

In this guide, I’ll explain the cross-docking meaning, what a cross-dock warehouse looks like, the benefits, and the challenges. By the end, you’ll see how this process keeps supply chains fast and efficient.

What is Cross-Docking: Meaning in Logistics

Cross-docking is a simple but powerful idea in logistics.

Instead of storing products in a warehouse for days or weeks, goods move directly from the truck that brings them in to the truck that takes them out

Think of it like a relay race where the baton is passed quickly, keeping things moving without delay. This process saves time, reduces storage costs, and gets products to customers faster.

Cross-docking is especially useful for businesses that deal with fast-moving goods, perishable items, or large retail orders where speed and efficiency matter most.

What Is a Cross-Dock Warehouse?

A cross-dock warehouse is a facility designed to keep products moving instead of storing them for long periods.

When shipments arrive, they are quickly unloaded, sorted, and moved directly onto outbound trucks headed for their next stop.

This process cuts down on storage costs, reduces handling, and speeds up delivery times.

Cross-dock warehouses are often laid out in simple shapes, like I-shaped or U-shaped designs, to make loading and unloading more efficient.

They’re especially useful for industries that need fast turnover, such as retail, food distribution, and manufacturing, where time and accuracy are critical to success.

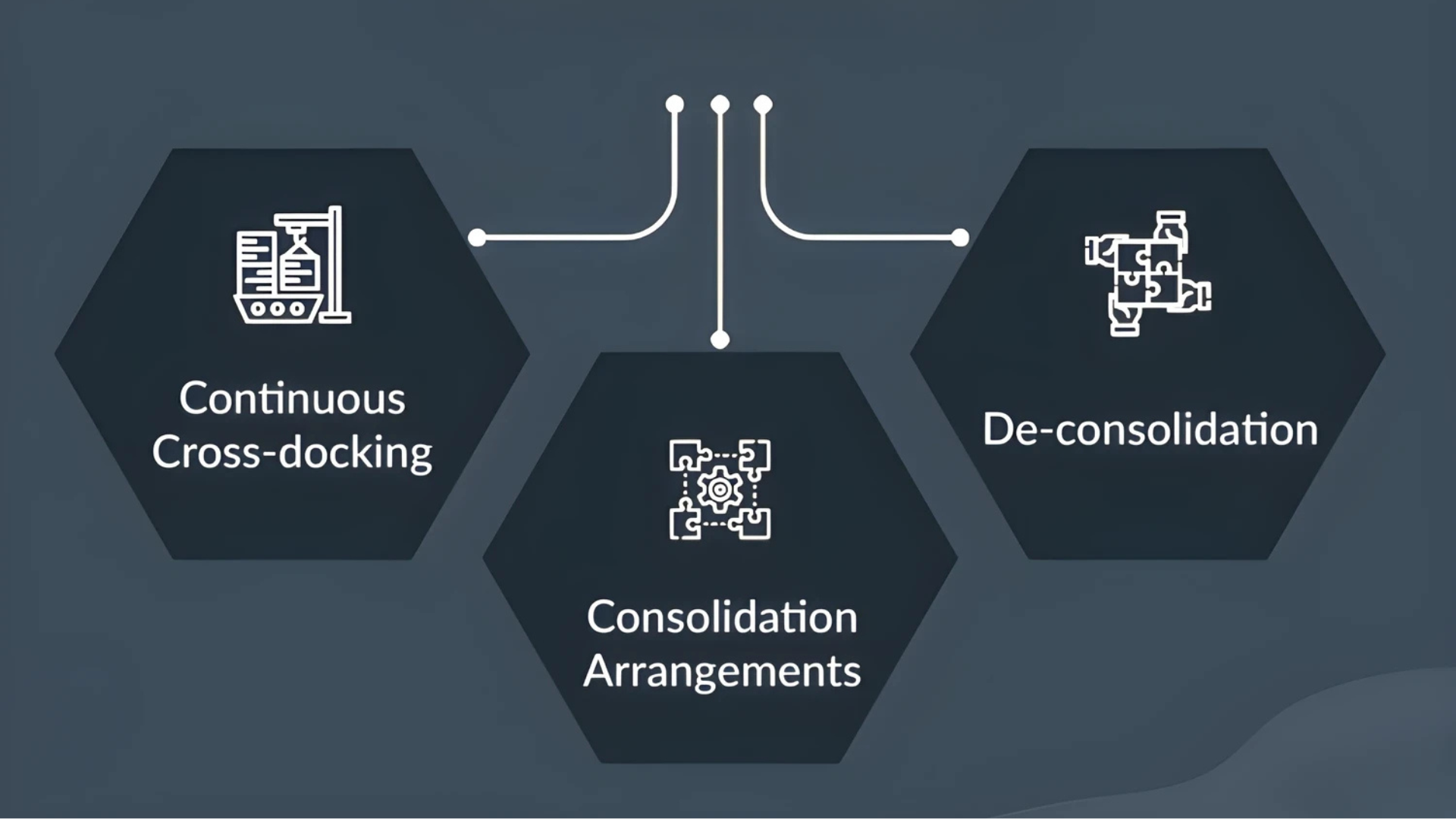

Common Types of Cross-Docking Methods

Cross-docking isn’t one-size-fits-all; different methods are used depending on the type of goods, volume, and delivery needs. Each approach helps companies manage products more efficiently.

1. Continuous Cross-Docking

Continuous cross-docking is the most straightforward approach. Goods are unloaded from inbound trucks and transferred directly to outbound trucks with little or no storage time.

This method is best for high-demand items, perishable goods, or fast-moving retail products.

Because products move so quickly, it reduces handling costs and helps ensure timely delivery. However, it requires precise scheduling and strong coordination between suppliers, carriers, and warehouse teams to avoid delays.

2. Consolidation Cross-Docking

Consolidation involves combining several smaller shipments into one larger load before sending it out.

This is useful for businesses that receive multiple small orders going to the same destination. By grouping them together, companies can save on transportation costs and maximize truck space.

Consolidation cross-docking also reduces the number of trips needed, which is better for both budgets and the environment. It does, however, require planning and sometimes short-term holding space.

3. Deconsolidation Cross-Docking

Deconsolidation works in the opposite way. A large shipment, often arriving in a full truckload or container, is broken down into smaller loads for delivery to multiple locations.

This method is common for distribution centers serving many retail stores. It allows products to spread out quickly across a region without long-term storage.

Deconsolidation helps reduce delivery times to final destinations but requires efficient sorting systems and careful labeling to avoid mix-ups.

Pre-Distribution vs. Post-Distribution Cross-Docking

Both pre-distribution and post-distribution cross-docking aim to speed up the flow of goods, but they work in different ways. Here’s a look at each:

Pre-Distribution Cross-Docking

In pre-distribution cross-docking, products are already sorted, labeled, and assigned to specific destinations before arriving at the cross-dock facility.

This means items can move almost immediately to outbound trucks with very little handling required. It speeds up the process and reduces errors, but it relies on accurate demand forecasting and strong supplier communication.

Pre-distribution is best for predictable orders and businesses with stable demand patterns.

Post-Distribution Cross-Docking

Post-distribution cross-docking adds flexibility by sorting and labeling goods after they arrive at the facility. This allows companies to adjust shipments based on current demand, store requirements, or last-minute changes.

While it takes more time than pre-distribution, it helps reduce overstocking and supports just-in-time inventory strategies.

Post-distribution is valuable in industries where demand can shift quickly, such as fashion retail or seasonal products.

Benefits and Challenges of Cross-Docking Warehouse

When I first looked into cross-docking, I saw how much it could help, but you also have to plan for the challenges that come with it.

Benefits

- Faster shipping and shorter delivery times

- Lower storage and handling costs

- Less risk of product damage since goods move quickly

- Better suited for perishable or fast-moving items

- Supports lean inventory and just-in-time strategies

Challenges

- Needs precise scheduling and coordination

- Higher setup and technology costs

- Not ideal for slow-moving or fragile goods

- Requires skilled staff and real-time data systems

Cross-docking can be a powerful tool, but success depends on using it in the right situations and with strong planning in place.

Cross-Docking vs. Traditional Warehousing

Cross-docking and traditional warehousing are two different approaches to handling goods. Understanding how they compare helps businesses choose the right fit for their needs.

| Feature | Cross-Docking | Traditional Warehousing |

|---|---|---|

| Storage | Minimal to no storage; goods move quickly in and out | Long-term storage of goods until needed |

| Speed | Fast transfers, ideal for urgent or perishable items | Slower, as products stay in inventory longer |

| Cost | Lower storage and handling costs | Higher storage and labor costs |

| Best For | High-volume, time-sensitive, or lean supply chains | Bulk stock, seasonal goods, or unpredictable demand |

Choosing between cross-docking and warehousing depends on product type, delivery timelines, and business goals. Both models have their place in modern supply chains.

Best Practices for Cross-Dock Warehouse Success

Running a cross-dock warehouse takes planning, the right tools, and smooth coordination. Following best practices helps ensure faster deliveries and fewer mistakes.

- Design efficient layouts – simple I-shaped or U-shaped designs reduce travel distance

- Use warehouse management systems (WMS) – real-time tracking keeps goods moving quickly

- Plan scheduling carefully – precise timing avoids bottlenecks and delays

- Train staff well – skilled teams handle transfers faster and more accurately

- Leverage data and forecasting – accurate demand planning supports smooth operations

With these practices in place, a cross-dock warehouse can run efficiently, cut costs, and deliver consistent results for businesses and customers alike.

Conclusion

Cross-docking is changing how you think about moving goods by focusing on speed, efficiency, and lower costs.

Instead of keeping products in storage, a cross-dock warehouse moves them quickly from supplier to customer with minimal delay. This reduces handling, lowers expenses, and helps you meet tight deadlines.

From my experience, the biggest advantage is how it supports lean, responsive supply chains. While it takes planning and coordination, the benefits often outweigh the challenges.

Once you understand the cross-docking meaning, you can decide if it’s the right solution.

For more straightforward tips on shipping and logistics, check out my other blogs for advice you can actually use.