Have you ever wondered what happens to products after we discard them? Most supply chains still follow a straight line: make, use, and discard.

However, today, more businesses are adopting a circular supply chain: a more efficient system that keeps materials in use rather than wasting them.

In this blog, I’ll walk you through what a circular supply chain really means, how it compares to the old linear model, the key practices behind it, and why it matters now.

You’ll also see the role of technology and a step-by-step guide to start building your own. By the end, you’ll know how you can join the move toward a more sustainable future.

Understanding Circular Supply Chains

A circular supply chain is a way of running supply chains that keeps products, materials, and resources in use for as long as possible. It differs from the traditional method of making and using products.

In a linear supply chain, resources are extracted, transformed into goods, used, and then discarded. This creates a straight path that ultimately leads to waste.

In a circular supply chain, the goal is to keep resources moving in a loop. Instead of products reaching the end of life and being discarded, they are reused, repaired, or recycled. This helps extend their life and reduces waste.

The main idea is to close the loop, thereby reducing the need for new resources. Businesses design products to last longer and plan how materials can be collected and reused.

This shift changes how products are designed, produced, and managed. It is not just about recycling at the end, but about building a system where nothing is wasted at any stage.

Circular vs Linear Supply Chains

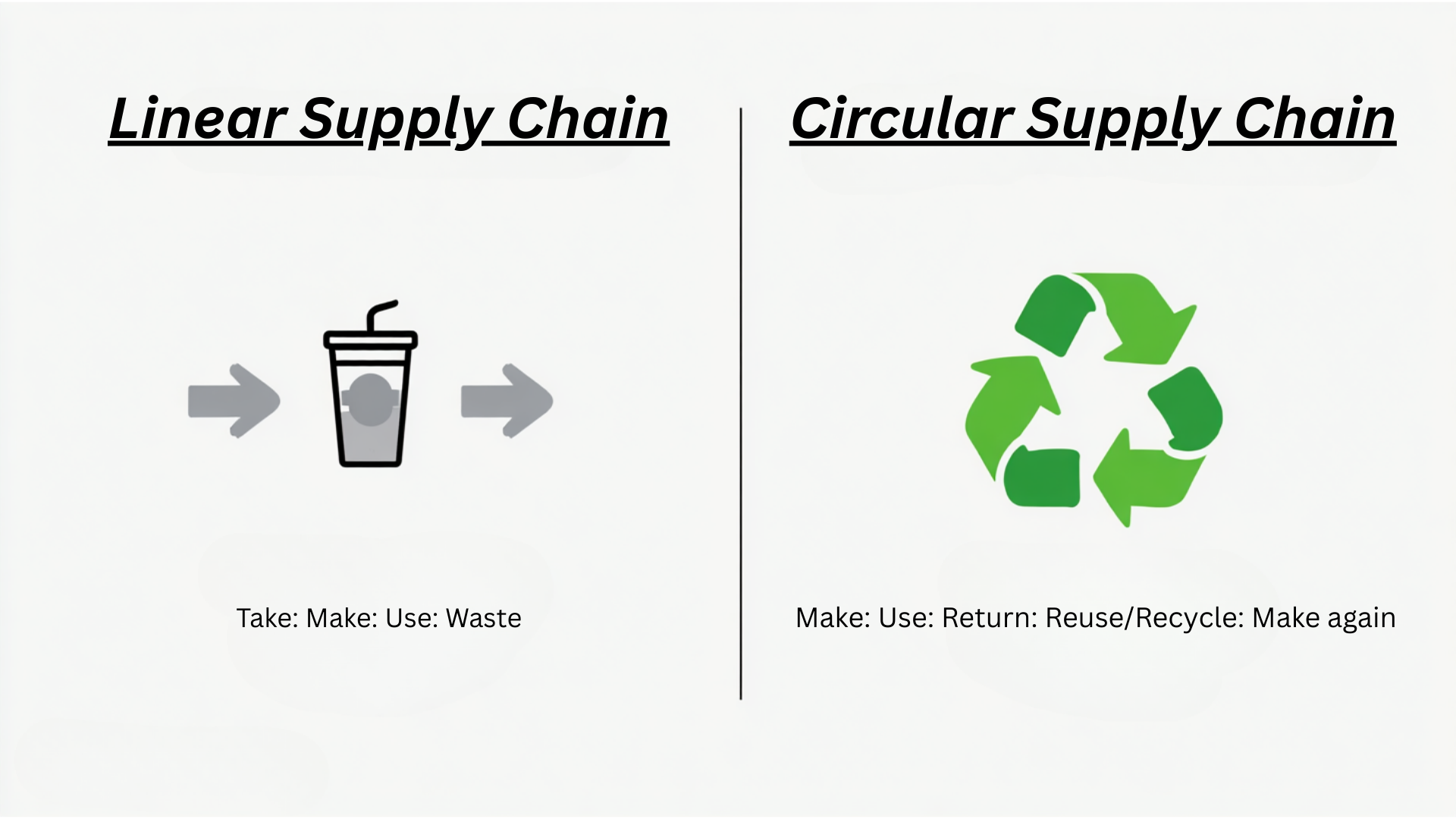

The table below illustrates the differences between circular and linear supply chains. Think of linear as a straight line that ends in waste, and circular as a loop where resources keep flowing back into use.

| Aspect | Linear Supply Chain | Circular Supply Chain |

|---|---|---|

| Flow | Take: Make: Use: Waste | Make: Use: Return: Reuse/Recycle: Make again |

| Resource Use | Uses raw materials once, then discards | Keeps resources in a loop, used many times |

| Product Design | Focused on short-term use | Designed for durability, repair, and recycling |

| End of Life | Products go to the landfill or incineration | Products are collected, refurbished, or remade |

| Visual | (straight line, ends in waste) | (closed loop, continuous cycle) |

In short, the circular model closes the loop on resources by keeping them in use longer and reducing waste.

Core Practices of a Circular Supply Chain

A circular supply chain works through a few core practices. These steps help products and materials stay useful for as long as possible:

- Longevity (Designing for Durability): Products are designed to last longer. Strong materials, modular parts, and timeless designs make items less likely to break or become outdated. This reduces the need to buy or produce replacements too often.

- Reuse (Keeping Products in Circulation): Instead of discarding, products are shared, resold, or passed on to others for continued use. Businesses can create systems for second-hand sales, rental programs, or product take-backs. This keeps items in circulation and reduces waste.

- Refurbish and Recycle Processes: Old or damaged products can be repaired and restored to working condition. If they cannot be reused, their parts and materials are recycled into new products. This ensures value is recovered instead of lost.

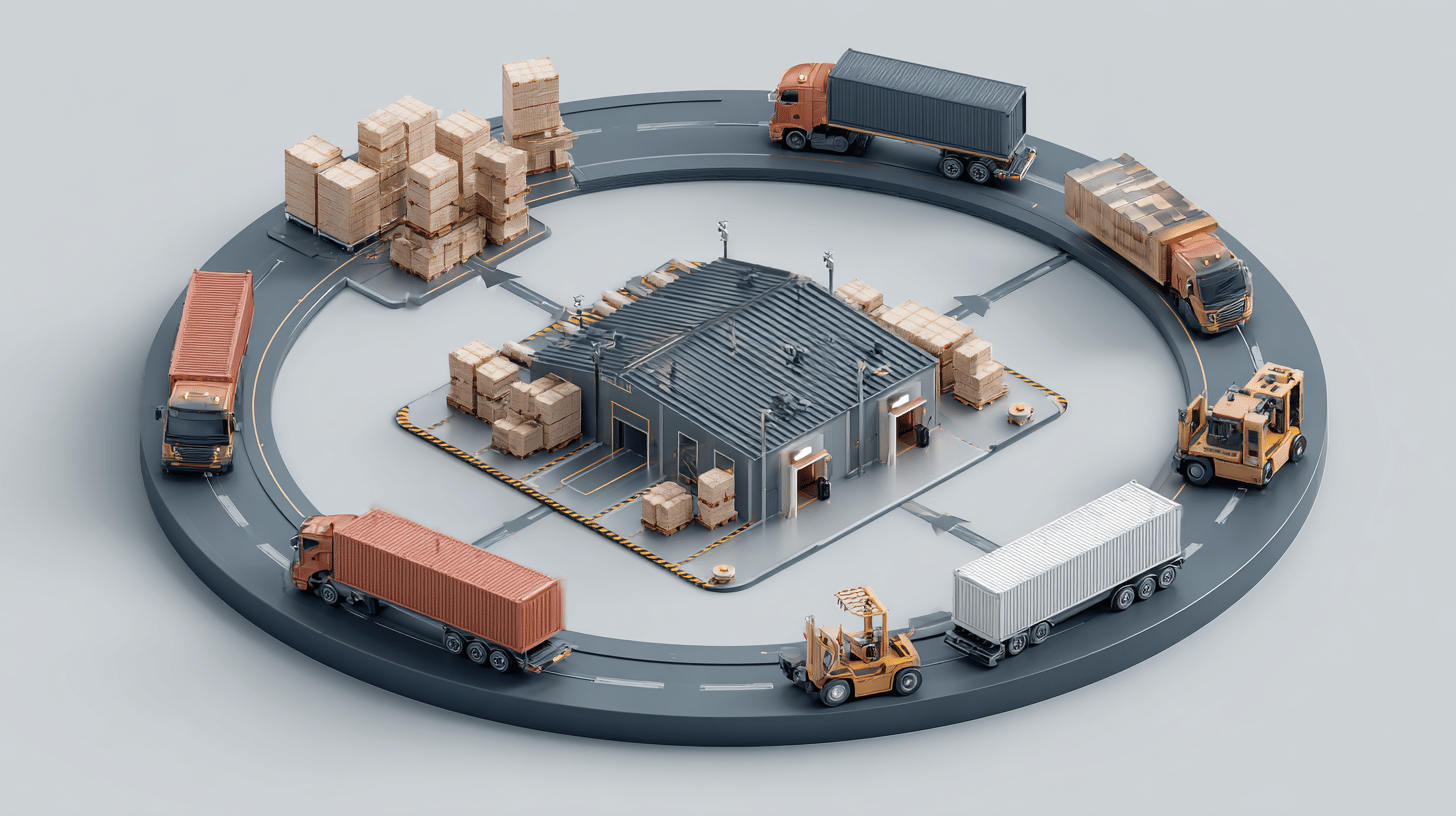

- Reverse Logistics as a Backbone: Reverse logistics is the system that brings used products back from customers. It covers collection, transport, sorting, and processing. Without reverse logistics, reuse, refurbishing, and recycling cannot happen at scale.

In short, circular supply chains shift the focus from waste to reuse. They change how products are designed, managed, and returned into the system. This foundation lays the groundwork for the core practices that make the model effective.

Why Circular Supply Chain Matters Now

Circular supply chains are becoming more important today. They address urgent environmental challenges while also creating substantial business advantages.

1. Environmental Gains

Circular systems reduce the strain on nature by lowering waste and emissions.

- Reducing waste: Products stay in use longer, which reduces landfill growth.

- Cutting carbon emissions: Recycling and reuse reduce the need for new raw materials and minimize the use of heavy production processes.

2. Economic & Cost Advantages

A circular approach makes better use of resources and opens new business opportunities.

- Improving resource efficiency: Companies save money by reusing parts and materials instead of buying new ones.

- Creating new revenue streams: Refurbished products, rental programs, and resale markets offer fresh ways to earn.

3. Competitive & Resilience Benefits

Circular supply chains strengthen a company’s market position and help it prepare for potential risks.

- Market differentiation: Businesses stand out by showing genuine sustainability efforts.

- Building supply chain stability: Reuse and recycling lower dependence on raw materials, making supply chains less vulnerable to disruptions.

Together, these benefits show why businesses are shifting toward circular supply chains now, not later.

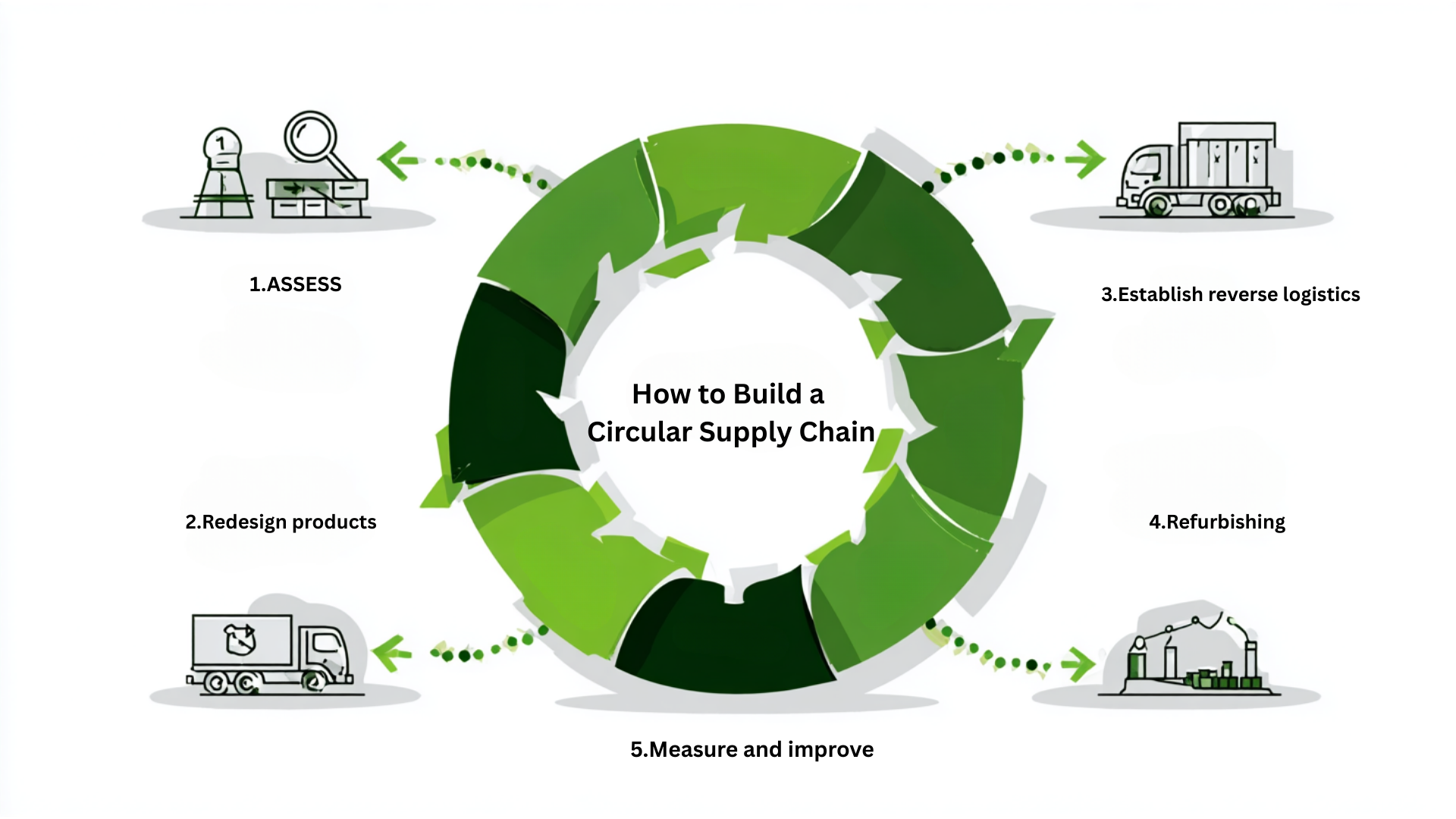

How to Build a Circular Supply Chain

Building a circular supply chain does not happen overnight. It requires a shift in mindset, product design, and operations.

The process begins by examining the current system, then gradually introducing loops that reintroduce products and materials into circulation.

Companies should begin with small steps, test new ideas, and learn what works in practice. By starting with pilot projects and scaling up gradually, businesses can mitigate risks while transitioning to a complete circular model.

Step 1: Assess the Current Supply Chain

- Map product flows from source to end of life.

- Find waste hotspots, returns, and rework.

- Set a baseline: return rate, recovery rate, cost, and CO₂ per unit.

- List quick wins and high-impact areas.

Step 2: Redesign Products for Longevity

- Use strong, repairable, and modular parts.

- Standardize screws and connectors for easy fixes.

- Pick recyclable or mono-materials where possible.

- Offer repair guides and spare parts.

Step 3: Establish Reverse Logistics & Collection

- Choose your preferred channel: drop-off, mail-back, or pickup.

- Add incentives, such as deposits, buy-back options, or rewards.

- Set sorting rules for reuse, repair, and recycle.

- Partner with 3PLs, recyclers, and repair hubs.

Step 4: Integrate Refurbishing/Remanufacturing Loops

- Triage items: reuse, repair, refurbish, remanufacture, recycle.

- Create simple work instructions and quality checks.

- Route parts back to production or to resale outlets.

- Secure markets for refurbished goods and recovered materials.

Step 5: Measure and Improve Using KPIs

- Track: return rate, recovery rate, reuse/refurb rate.

- Track: CO₂ saved, cost per recovered unit, lead time to recovery.

- Track: % revenue from circular offers and customer repeat rate.

- Review monthly, identify and address bottlenecks, and expand pilots.

A circular supply chain is built incrementally. The key is to strike a balance between ambition and practical action.

By measuring progress and scaling successful practices, businesses can transform their supply chains into systems that are cost-effective, sustainable, and resilient for the future.

Technology Enablers of Supply Chain

Technology plays a crucial role in enabling circular supply chains. It helps track products, predict demand, and manage the flow of materials across various stages of the supply chain. A few of them are listed below:

1. AI and Predictive Analytics

Artificial intelligence can forecast demand, track returns, and estimate product life cycles. It helps companies understand how long items will stay in use before needing attention.

With this insight, businesses can predict when repairs or replacement parts will be required. This allows them to stay prepared and avoid costly delays.

AI also makes inventory planning smarter. It ensures materials are ready for reuse when needed and reduces overproduction by matching supply more closely with actual demand.

2. Blockchain for Traceability

Blockchain creates secure and transparent records of product journeys. It tracks materials from sourcing to recycling, providing businesses with a clear view of where resources originate and where they ultimately end up.

It also provides proof of authenticity for refurbished products, which helps reduce fraud and builds confidence in second-hand markets. By sharing transparent data, blockchain enhances trust among companies, customers, and partners throughout the supply chain.

3. IoT and Digital Twins for Lifecycle Tracking

IoT devices and digital twins provide real-time visibility into how products are used. Sensors track performance in the field and share valuable data.

Digital twins simulate product lifecycles and can even predict failures before they happen. This allows businesses to act early and plan repairs or part replacements.

With accurate data, companies can better manage reuse, recycling, and recovery. These technologies make circular supply chains more reliable and efficient by ensuring every product is tracked and managed with less effort and higher accuracy.

Case Studies by Industry

Circular supply chains vary in structure across different industries. Each sector adapts the model in ways that fit its products, customer needs, and challenges.

1. Electronics and Urban Mining

Electronics contain valuable metals, including gold, copper, and rare earths. Urban mining recovers these materials from discarded phones, laptops, and other devices.

- Companies refurbish used electronics for resale.

- Materials from broken devices are extracted and recycled for reuse.

- This reduces the need for raw mining and lowers e-waste.

2. Fashion and Apparel Returns

The fashion industry produces massive textile waste. Circular practices help reduce it.

- Brands offer clothing take-back programs for resale or recycling.

- Returned items are repaired and sold as second-hand.

- Old textiles are broken down and turned into new fabrics.

3. Automotive and Spare Parts Loops

Automotive supply chains are shifting toward reuse and remanufacturing.

- Car makers collect used parts and refurbish them for resale.

- Engines, gearboxes, and batteries are given a second life.

- Scrap materials, such as steel and aluminum, are recycled.

4. Food Supply Chain Innovations

Food waste is another global challenge, and circular ideas are making progress.

- Unsold food is redirected to charities or food banks.

- Organic waste is turned into compost or bioenergy.

- Packaging is redesigned for reuse or easier recycling.

These examples demonstrate that circular supply chains are not a one-size-fits-all solution. Each industry applies the concept differently, but the common goal remains the same: keep resources in use and reduce waste.

Circular Supply Chain: Measuring Success

To determine if a circular supply chain is effective, businesses require clear metrics. These key performance indicators (KPIs) demonstrate the effectiveness of resource reuse and waste reduction.

Benchmarks from different industries also give valid points of comparison.

| Metric | What It Measures | Example Benchmark |

|---|---|---|

| Resource Efficiency | How well materials are reused instead of being replaced | Electronics: up to 70% of metals recovered through urban mining |

| Waste Reduction | Amount of waste diverted from landfill or incineration | Fashion: Some brands collect and reuse 40% of returned clothing |

| CO₂ Savings | Reduction in greenhouse gas emissions | Automotive: remanufactured parts cut emissions by 30–40% compared to new production |

By tracking these KPIs, companies can see both environmental and financial gains. Regular benchmarking helps identify gaps, highlight progress, and guide continuous improvement.

Common Roadblocks in Circular Supply Chains

While circular supply chains offer many benefits, they are not easy to build. Businesses often face obstacles that slow down adoption.

Some of the most common challenges include:

- High Upfront Implementation Costs: Transitioning to a circular model necessitates significant investments in new designs, systems, and processes. These costs can seem high at first, even if savings appear later.

- Reverse Logistics Complexities: Collecting products after use, sorting them, and returning them to circulation requires strong logistics. Building such systems can be complex and resource-heavy.

- Data, Traceability, and Technology Gaps: Tracking products through their entire life cycle needs accurate data and advanced tools. Many companies struggle with traceability and the lack of digital systems to support it.

These barriers are real, but they can be overcome with planning, partnerships, and the right technology. Over time, the long-term gains outweigh the early challenges.

The Future of Circular Supply Chains

The future of supply chains is shifting toward circular models. Global rules, business leadership, and emerging technologies will accelerate adoption in the coming years.

1. Global Regulations and Initiatives

Governments and global organizations are setting stronger rules for sustainability. The European Union has policies in place to promote recycling, eco-design, and the reuse of resources.

The World Economic Forum (WEF) supports global collaboration on circular systems, and the Ellen MacArthur Foundation shares research and tools that help companies make the shift.

2. Role of Procurement Leaders in Adoption

Procurement teams play a critical role in advancing circular practices by shaping how materials and products move through the supply chain.

By selecting suppliers that prioritize recycled or long-lasting materials, they directly support sustainable production. They can also push for greater transparency in sourcing and manufacturing processes, ensuring accountability at every stage.

Ultimately, their choices influence not only immediate purchasing decisions but also set the tone for the entire supply chain, encouraging broader adoption of responsible, circular business models.

3. Emerging Trends Shaping the Next Decade

Several trends are expected to define the next wave of circular supply chains.

- Greater use of digital tools, such as AI, IoT, and blockchain, for enhanced visibility.

- Growth of product-as-a-service models, where customers rent instead of buying.

- Stronger consumer demand for sustainable products and packaging.

The future of circular supply chains will be built on cooperation between governments, companies, and customers. Those who act early will be better prepared for both regulatory changes and market shifts.

Wrapping Up

We’ve seen how circular supply chains differ from linear ones, the core practices that keep resources in use, the benefits they bring, the challenges to overcome, and even how industries are already applying them.

I believe moving toward circular models is no longer optional: it’s the future. If you’re starting, begin small: assess, redesign, and measure.

Over time, you’ll build a system that saves costs, reduces waste, and makes your business resilient.

Now it’s your turn: are you ready to take the first step toward building a sustainable circular supply chain? Drop your ideas below!

Frequently Asked Questions

Can a circular supply chain work for service-based businesses?

Yes. Even service companies utilize products such as electronics, furniture, and uniforms. By reusing, repairing, or recycling these, they can still apply circular practices.

How do circular supply chains affect customer trust?

When businesses demonstrate that they are reducing waste and reusing materials, customers perceive them as responsible and future-focused. This builds stronger loyalty.

Are circular supply chains only for large companies?

No. Small and medium-sized businesses can start with simple steps, such as implementing product take-back programs or switching to recyclable packaging.

What skills do teams need to manage a circular supply chain?

Teams benefit from knowledge in data tracking, supplier partnerships, and sustainable product design. Clear communication and problem-solving are also key.