When I first heard the term blind shipping, I wasn’t sure what it really meant. Over time, I learned that it’s a process many businesses use to protect supplier details and keep their brand front and center.

If you’ve ever asked yourself, “What is blind shipping?” It’s basically when a supplier sends goods directly to a customer, but the labels and paperwork only show the retailer’s name.

This way, the customer never knows where the order originally came from. I’ve found this method especially useful for e-commerce stores, wholesalers, and businesses working with multiple suppliers.

In this post, I’ll explain how blind shipping works and why it can make a big difference in logistics and customer relationships.

What is Blind Shipping?

Blind shipping is when products are sent from a supplier to a customer without showing the supplier’s identity.

Instead, the shipping labels and documents display the retailer’s or distributor’s name, making it appear that the order came directly from the business the customer purchased from.

The blind shipment meaning is that the customer is “blind” to where the goods were shipped from. This protects supplier information, keeps pricing private, and presents a consistent brand image.

There are two types: in a single-blind shipment, the customer doesn’t know the supplier, but the supplier knows the customer.

In a double-blind shipment, both sides are hidden, and a third party manages the process to protect relationships and maintain brand consistency.

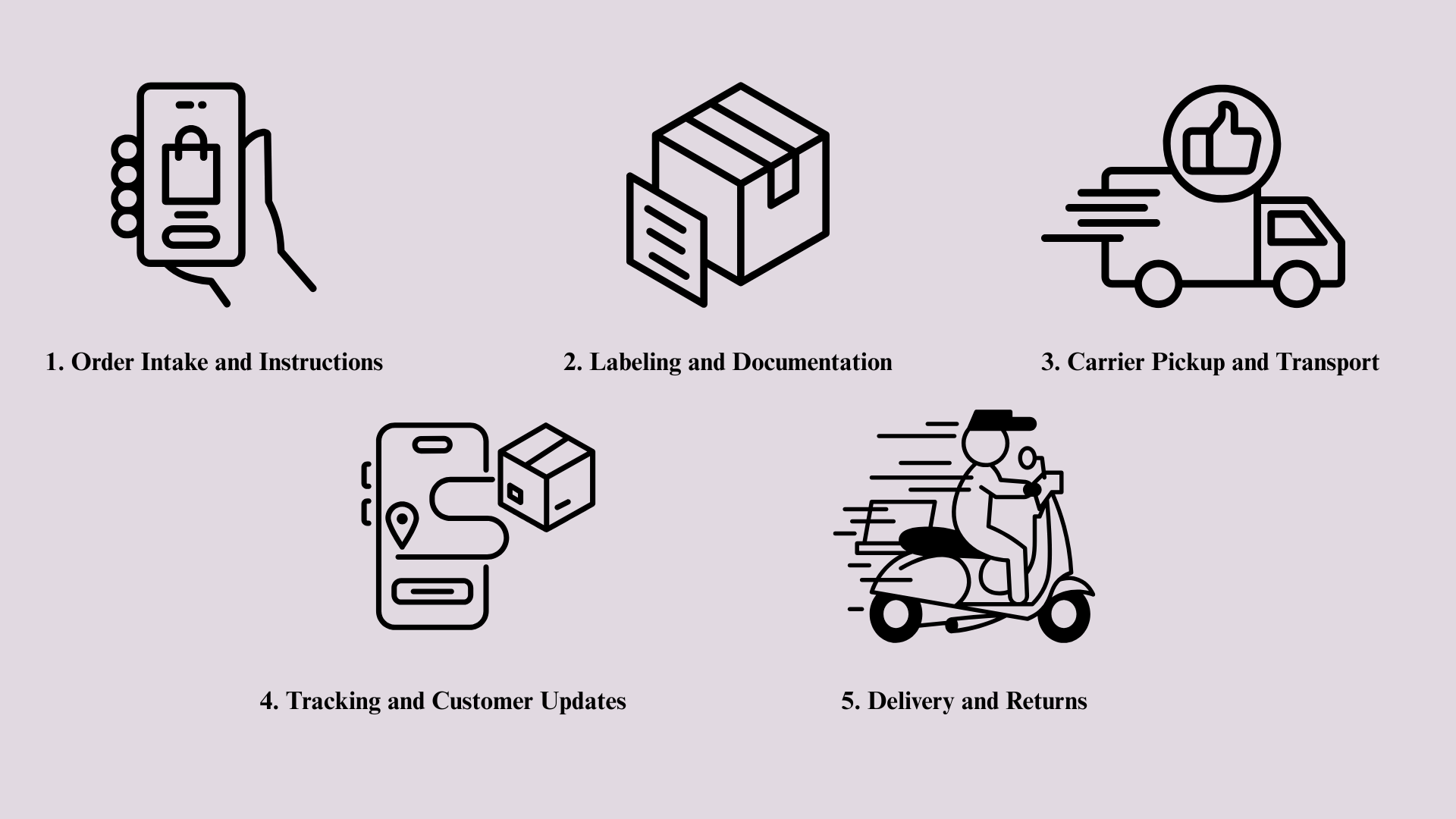

Step-by-Step Workflow of Blind Shipping

When I first looked into blind shipping, I realized the process can feel confusing at first. But once you break it down into steps, it’s actually very structured.

Each stage is designed to move the order smoothly while keeping supplier details hidden.

1. Order Intake and Instructions

The process starts when the retailer receives an order from the customer. At this point, the retailer sets clear rules for blind shipping.

These rules outline which details to hide, such as the supplier’s name or address, and what information should appear instead, like the retailer’s brand name.

2. Labeling and Documentation

Once the order is confirmed, labels and shipping documents are created. Unlike standard shipping, these documents don’t reveal the supplier’s identity.

The packing slip, invoice, and return address are adjusted to reflect the retailer’s brand or a neutral label.

Some businesses even add their logo or customer service number so the package looks like it came directly from them.

3. Carrier Pickup and Transport

After labeling, the carrier picks up the package directly from the supplier’s warehouse or a third-party logistics provider.

Even though the package is leaving from the supplier’s location, the paperwork and tracking information point back to the retailer.

This allows the retailer to stay “in front” of the customer while still relying on the supplier for fulfillment.

4. Tracking and Customer Updates

Once the carrier has the package, tracking information is shared with the retailer, who then passes it to the customer.

This step is often done through branded emails or an online portal, so the customer feels they’re interacting only with the retailer.

Even though the supplier is doing the shipping, the retailer maintains control of communication and customer touchpoints.

5. Delivery and Returns

The customer receives the package with no sign of the supplier’s involvement. If a return is needed, the process follows the retailer’s system.

The return address is either the retailer’s warehouse, a 3PL facility, or a neutral location set up for blind shipments. This ensures customers don’t bypass the retailer and contact the supplier directly.

Required Documents & Data Fields for Blind Shipping

Blind shipping only works if the paperwork is prepared correctly. The goal is to make sure the customer sees the retailer’s information while the supplier’s details remain hidden.

- Bill of Lading (BOL): Must show the retailer or a neutral shipper, not the supplier. Some carriers may require special “blind” instructions.

- Packing Slip: Adjusted to remove supplier details; should display retailer’s name, order number, and customer service contact.

- Invoice: The customer copy hides supplier info, while the retailer keeps the original supplier invoice for accounting.

- Return Address: Must be branded or neutral so the supplier isn’t revealed during returns.

- Tracking Number: Shared through the retailer’s system, keeping all customer communication consistent.

By handling these documents carefully, blind shipments stay accurate, compliant, and brand-friendly without confusing the customer.

Blind Shipping vs. Dropshipping: Key Differences

When I first learned about blind shipping, I noticed people often mix it up with dropshipping. While they sound similar, they aren’t the same.

Both methods let suppliers ship directly to customers, but the way branding and information are handled makes all the difference.

| Feature | Blind Shipping | Dropshipping |

|---|---|---|

| Supplier Identity | Hidden from the customer, labels show the retailer’s name or are neutral. | Visible or sometimes included on documents. |

| Brand Control | Retailer’s branding is shown on labels, slips, and communication. | Supplier branding or generic packaging is common. |

| Customer Experience | The customer believes the retailer shipped the order. | The customer may realize the order came from the supplier. |

| Inventory | A retailer may hold no inventory but controls documents and labels. | Retailer holds no inventory; supplier fulfills fully. |

| Best For | Protecting supplier info and strengthening brand image. | Quick startup with minimal control over presentation. |

Blind shipping gives retailers more control over branding and privacy, while dropshipping focuses more on convenience and speed.

Blind Shipping Benefits & Risks

Blind shipping comes with clear advantages, but it also has a few challenges. Knowing the benefits, risks, and ways to manage them helps businesses use it effectively.

| Benefits of Blind Shipping | Risks of Blind Shipping |

|---|---|

| Protects supplier information – customers never see the real supplier. | Labeling mistakes – wrong slips or return info may reveal the supplier. |

| Stronger brand identity – packaging and documents reflect the retailer’s name. | Returns confusion – customers may try to send items back to the supplier. |

| Faster fulfillment – products ship directly from the supplier without extra steps. | Carrier compliance issues – some carriers require accurate BOL details. |

| Cost savings – avoids storing or handling goods at multiple locations. | Customer trust risks – mistakes can make the order look unprofessional. |

The best way to reduce blind shipping risks is by setting up clear systems and procedures. Retailers should create standard templates for labels, packing slips, and BOLs to prevent mistakes.

Using a reliable 3PL or logistics partner can help ensure accuracy, while staff training keeps everyone on the same page.

Regular audits and test shipments also help catch errors before they reach the customer. With the right preparation, blind shipping can be both efficient and safe.

Blind Shipment Meaning for E-commerce, Wholesale, and 3PLs

Blind shipment’s meaning shifts depending on the type of business.

For e-commerce brands, it allows them to keep a consistent look and protect supplier details.

In wholesale and distribution, it helps resellers protect their supplier list while still serving multiple customers.

For private label sellers and multi-supplier catalogs, it’s almost a must-have, since customers expect all products to appear as if they came from one source.

When working with a 3PL (third-party logistics provider), it’s important to check their capabilities. Ask if they can:

- Generate custom labels that show your brand.

- Mask supplier details on invoices and packing slips.

- Provide portal roles and permissions so only approved users see full shipment data.

Providers like GlobalTranz and Worldwide Express highlight these features, making blind shipping easier and more reliable for retailers.

Blind Shipment Setup Checklist

Getting blind shipping right means setting up strong processes before the first order goes out. Below is a simple checklist you can follow:

- Define your policy: Decide if you’ll use single-blind (customer doesn’t see supplier) or double-blind (supplier and customer don’t see each other).

- Update templates: Lock your invoice and packing slip designs so they never display supplier details.

- Prepare BOLs: Create a blind Bill of Lading template with clear notes for carriers.

- Return workflow: Set up branded or neutral return addresses and a clear RMA process.

- System testing: Run test orders through labeling, tracking, and proof of delivery to catch errors early.

By following this checklist, you’ll reduce mistakes and make sure blind shipments always look professional and brand-focused.

Conclusion

Blind shipping may seem complicated at first, but once it’s set up, it becomes a powerful way to protect supplier details and strengthen your brand.

If you’ve ever wondered, “What is blind shipping?” It’s essentially about delivering orders directly from suppliers while keeping the retailer’s name front and center.

This method saves time, cuts costs, and creates a smooth customer experience where the retailer is seen as the true source. I’ve seen that businesses working closely with their 3PLs and carriers get the best results, since consistency matters.

For more straightforward guides on shipping methods, logistics strategies, and fulfillment tips, explore my other blogs to find the solutions that fit your business best.